D-1.2 DWV Terminology

Terminology: NPC Definitions for DWV Systems

Standardized terminology is an important communication tool for interpreting code regulations and for on-site communication with co-workers and local inspectors. For professional plumbers, knowing these terms and their applications is essential.

This section defines key terms related to DWV (Drainage, Waste, and Vent) Systems, many of which be used throughout Block D: Drainage Systems. The terminology provided here is based on the 2020 National Plumbing Code (NPC), available online.

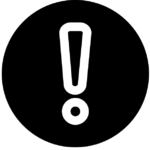

additional circuit vent: a vent pipe installed between a circuit vent and a relief vent (Figure 1) to provide additional air circulation.

air admittance valves: mechanical valves that simulate vents. They allow air to be drawn into the waste plumbing system under negative pressure to prevent siphoning but prevent any air from escaping the plumbing system under positive pressure. Air admittance valves (Figure 2) should be installed in an accessible, ventilated area. These devices are sometimes an acceptable alternative to conventional venting in applications where installing a conventional vent is not possible.

To meet the conditions required by British Columbia Plumbing Code, ensure that your valve conforms to the ASSE 1051 standard.

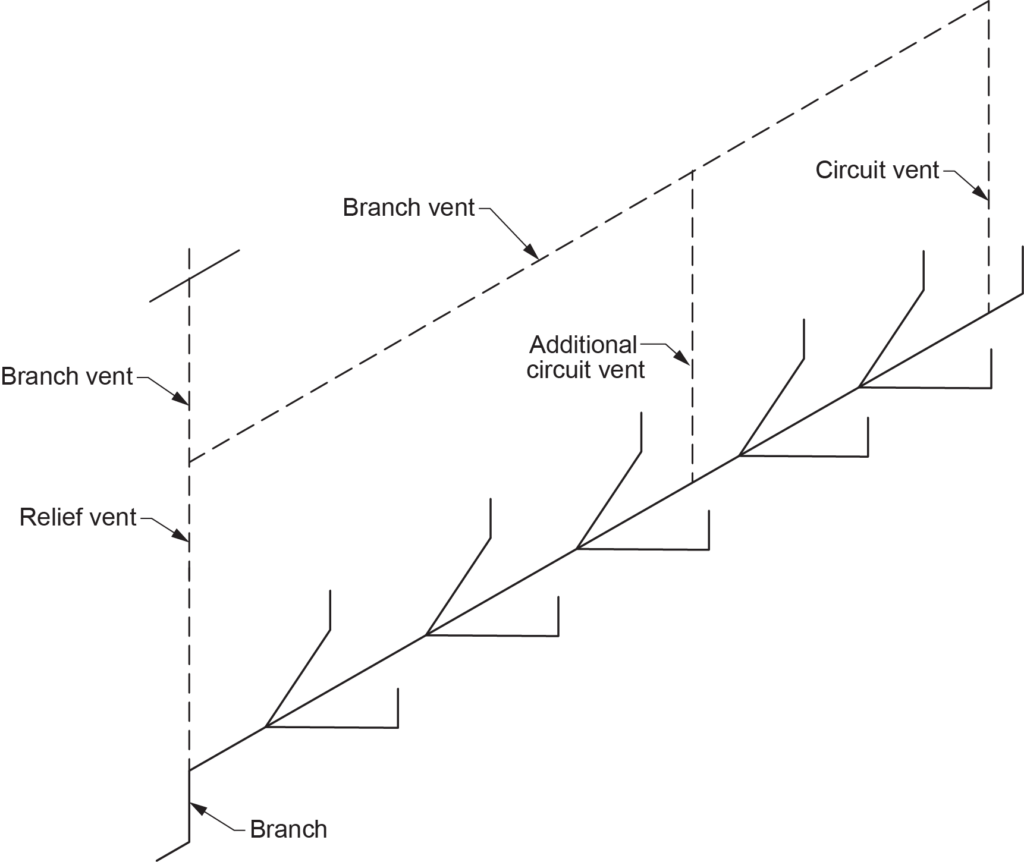

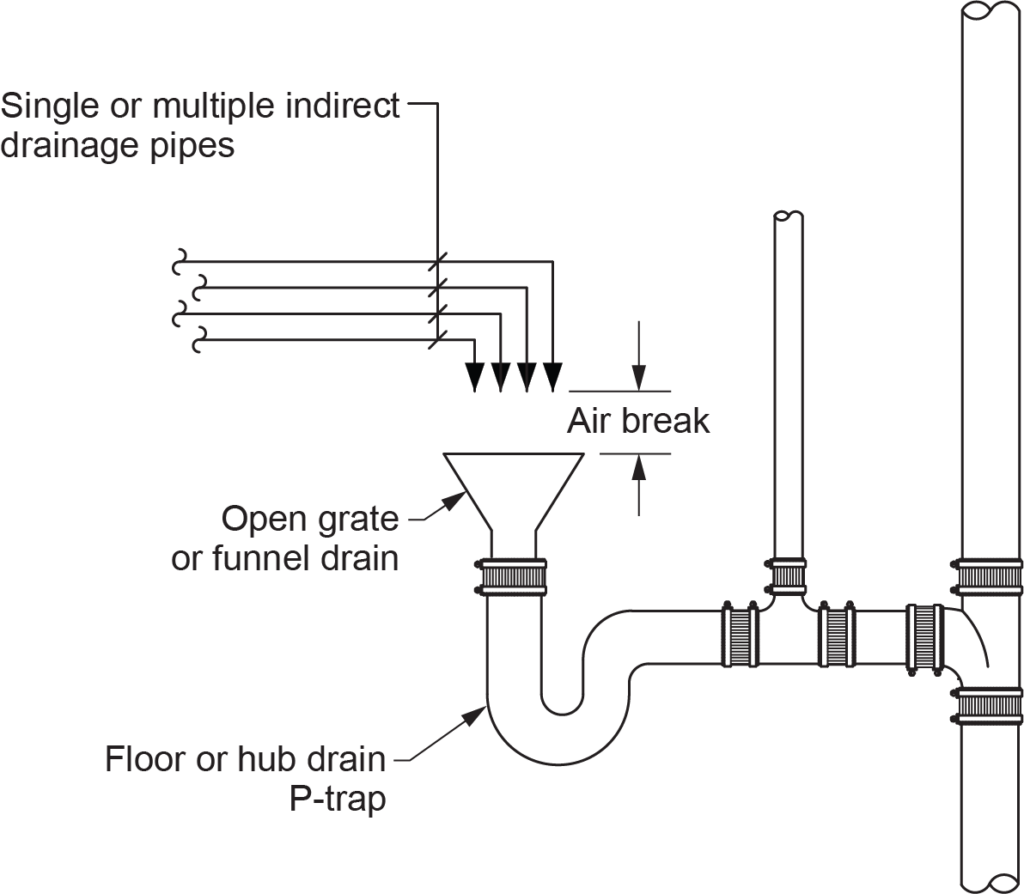

air break: a method of indirectly connecting a drainage pipe to another drainage pipe. An air break (Figure 3) is created by leaving an unobstructed vertical gap between the discharge of a fixture and the receptacle that receives it. This distance must be at least 25 mm (1 in.) or the size of the upper drain pipe, whichever is greater. This is commonly used to protect fixtures used to store and prepare food, drinking fountains, ice makers, and many other devices that must be protected from contamination due to a direct connection.

authority having jurisdiction (AHJ): the governmental body responsible for enforcing any part of the NPC.

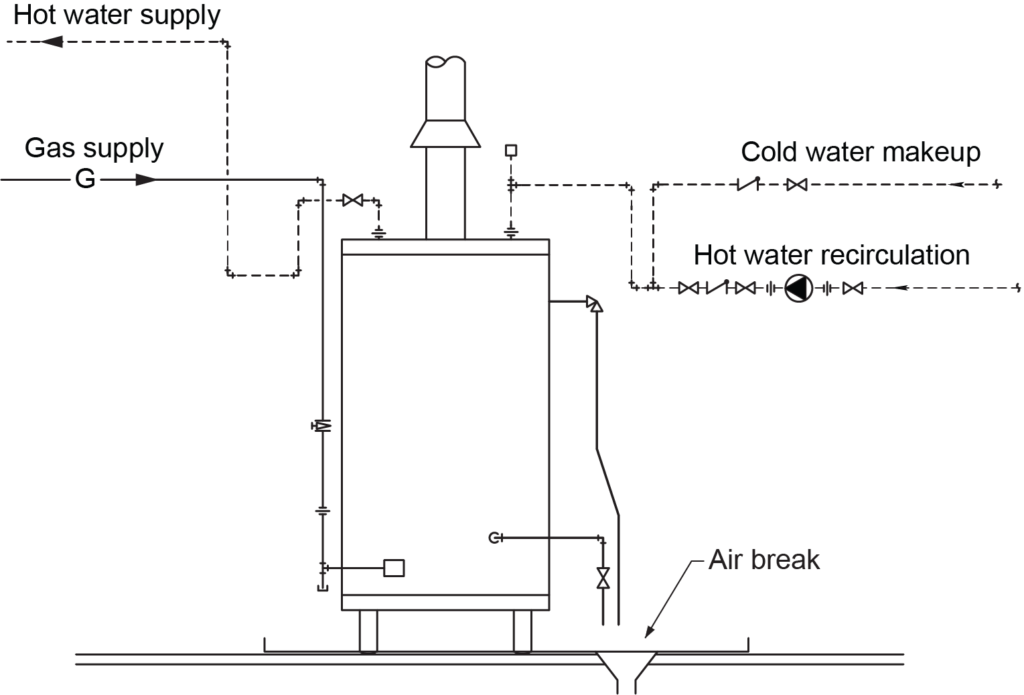

backflow: a reversal of the normal direction of the flow.

backwater valve: a one-way flow control valve installed in a drainage system. Backwater valves (Figure 4) are required to protect fixtures and drainage openings installed below grade, such as in a basement, where the possibility exists for the municipal sewage or stormwater systems to become overloaded and force wastewater back through your drains. Backwater valves are also required on any subsoil drainage pipe that connects into the sanitary drain to protect it from sewage backups.

Under normal conditions, it allows the wastewater to drain out of the system (Figure 5), but if a reversal of flow should occur, the valve is forced closed and protects the interior of the building from sewage backup.

bathroom group: a group of plumbing fixtures installed in the same room, consisting of one domestic lavatory, one water closet, and either one bathtub (with or without a shower) or one single-head shower. The intent is that these three fixtures are located in a room occupied by only one person, so they are not normally in simultaneous use.

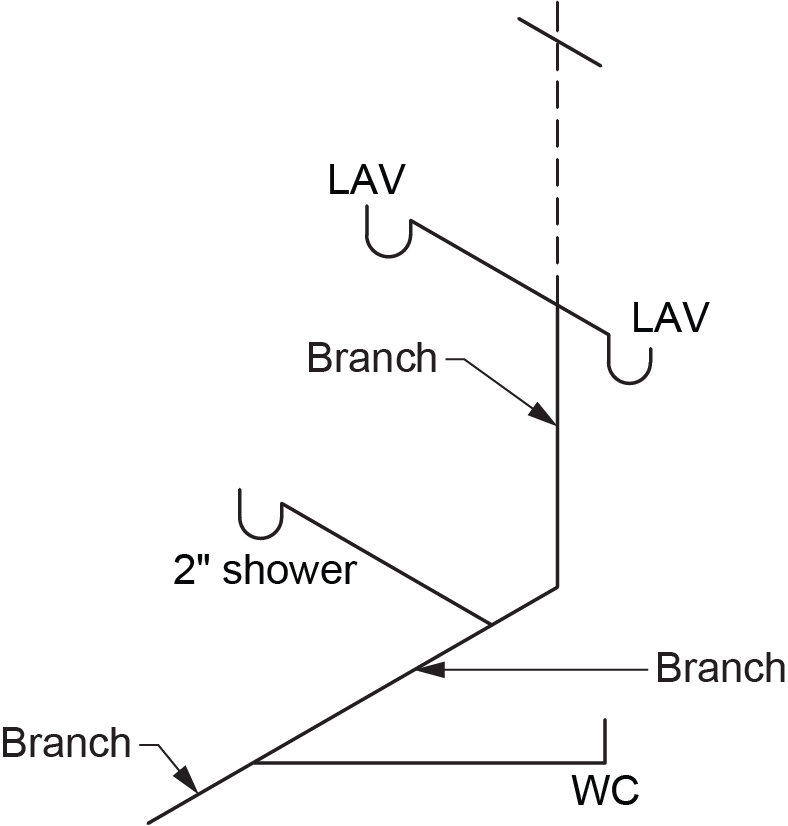

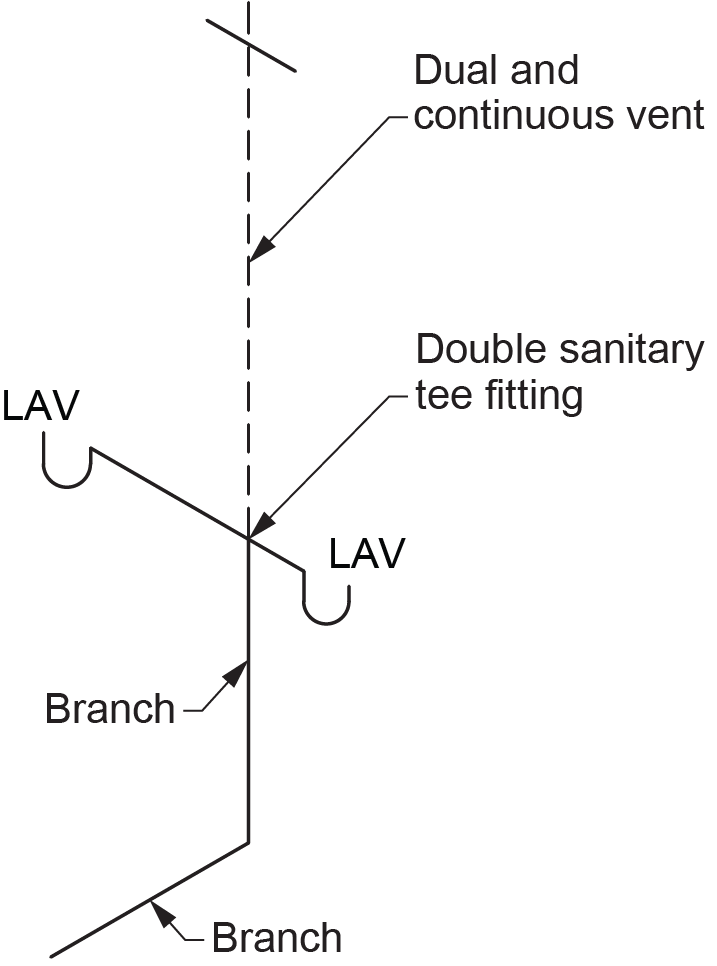

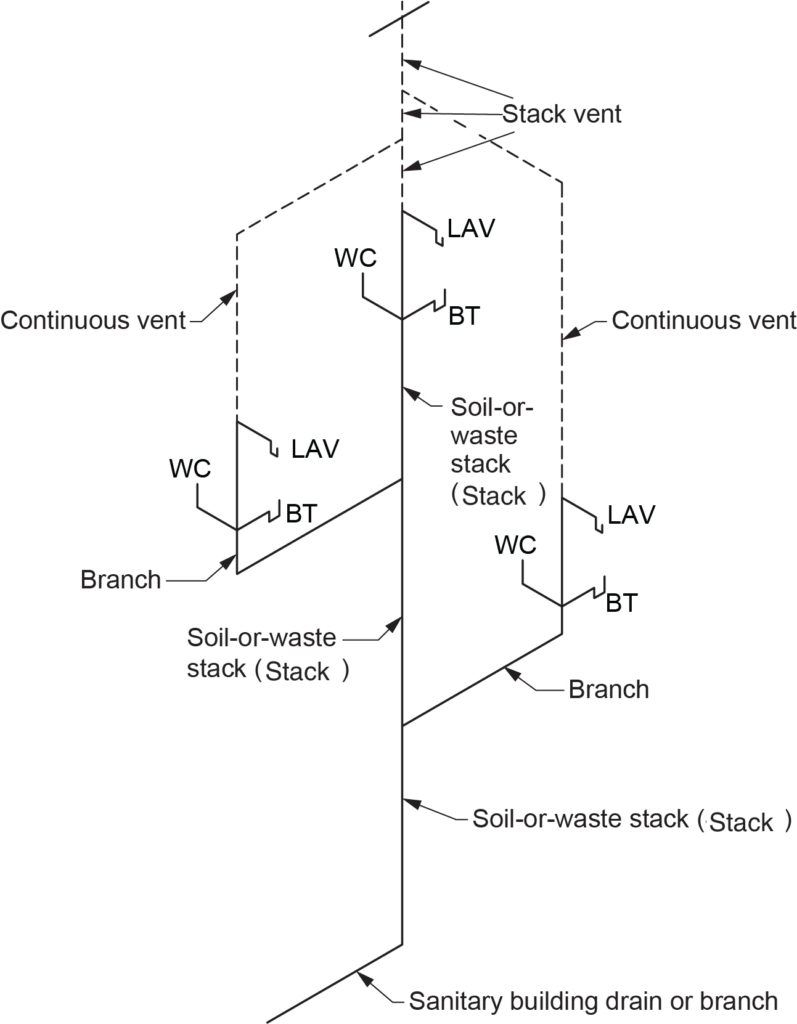

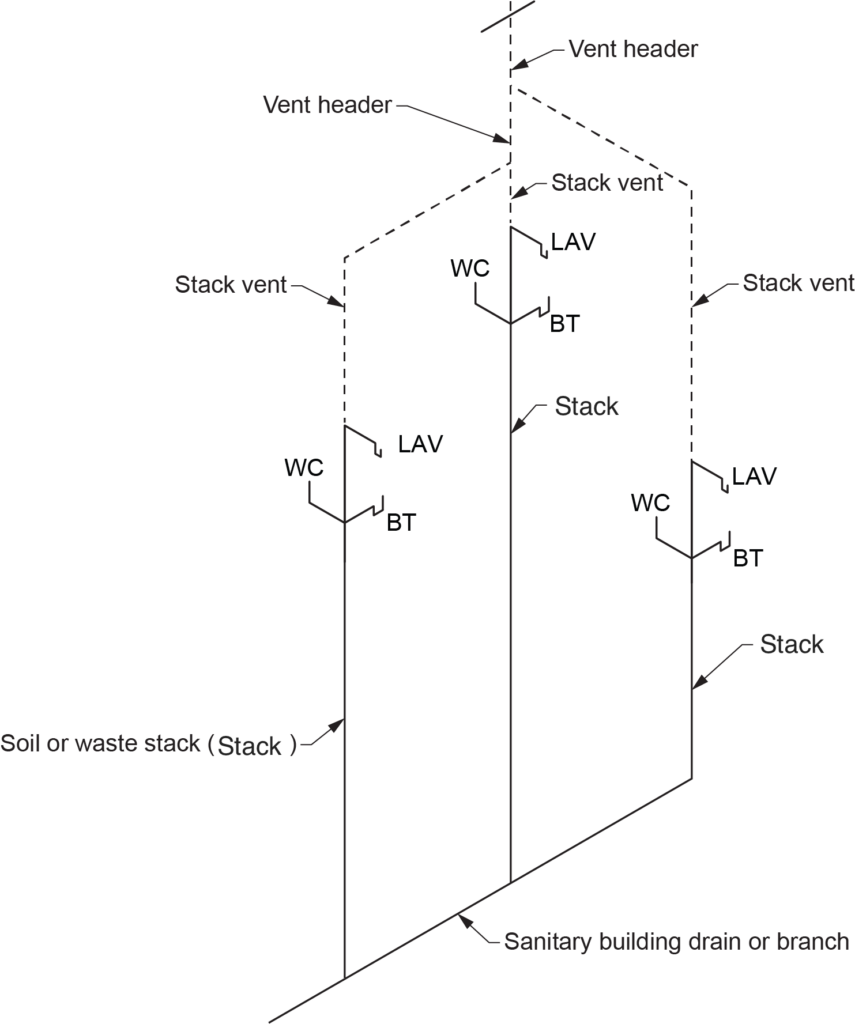

branch: a sanitary drainage pipe connected at its upstream end to the junction of two or more sanitary drainage pipes or to a stack and connected at its downstream end to another branch, a sump, a stack, or a building drain (Figure 6).

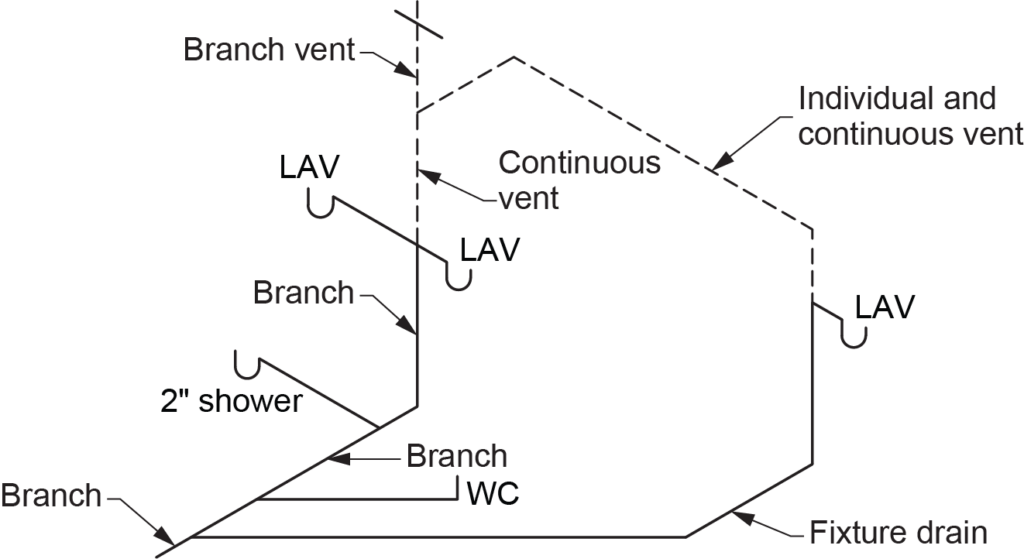

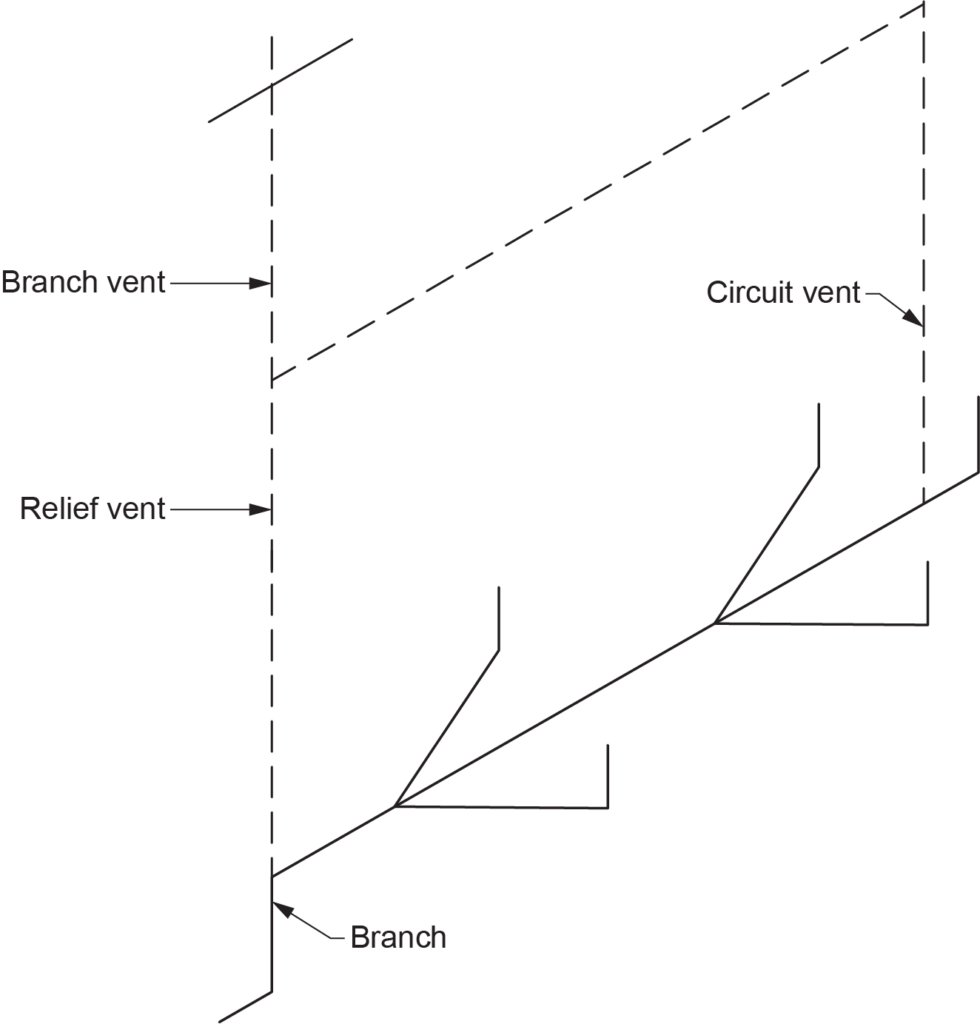

branch vent: a vent pipe connected at its lower end to the junction of two or more vent pipes. At its upper end, it either terminates in the open air or connects to another branch vent, stack vent, vent stack, or vent header (Figure 7).

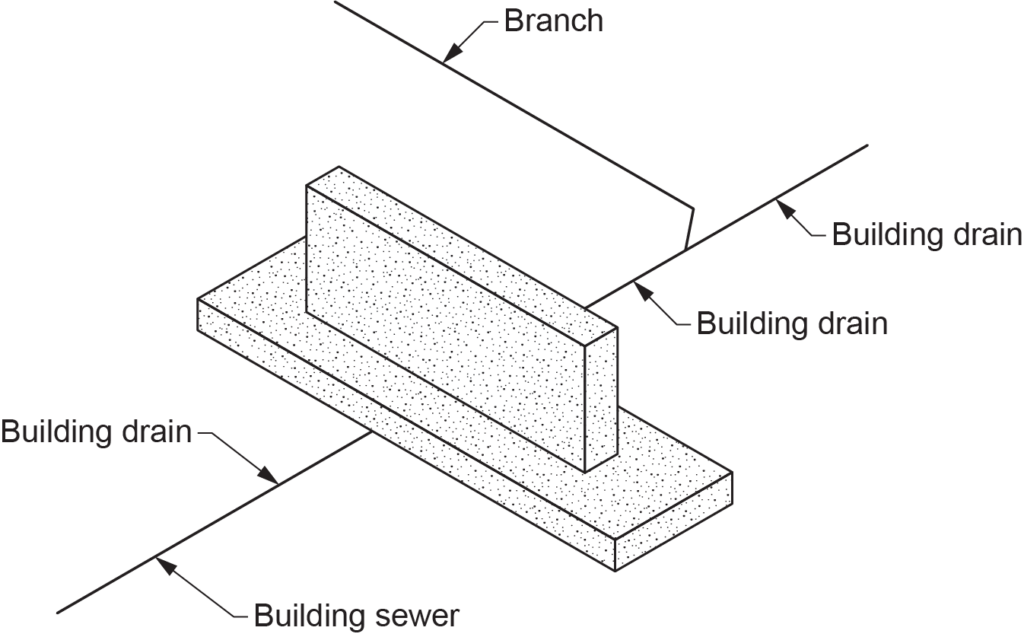

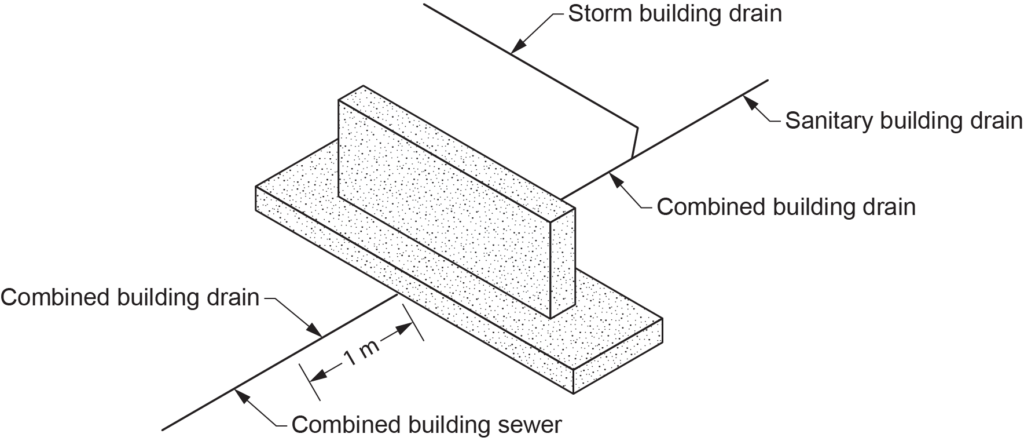

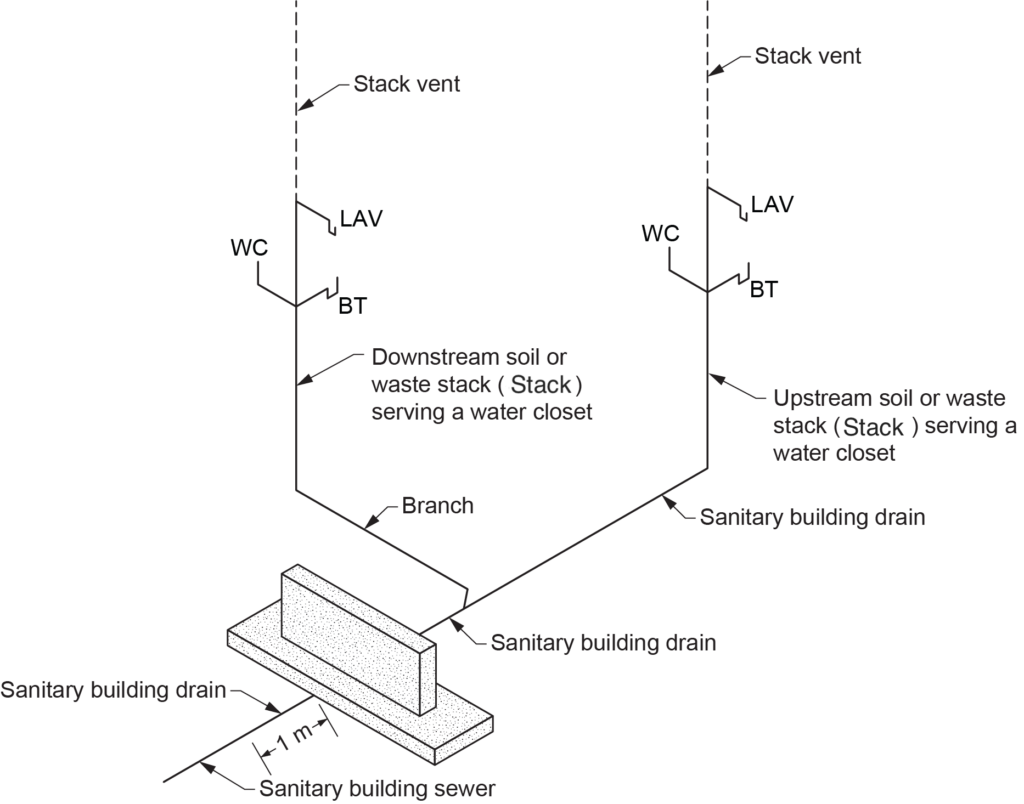

building drain: the lowest horizontal piping, including any vertical offset that conducts sewage, clear-water waste, or stormwater by gravity to a building sewer (Figure 8).

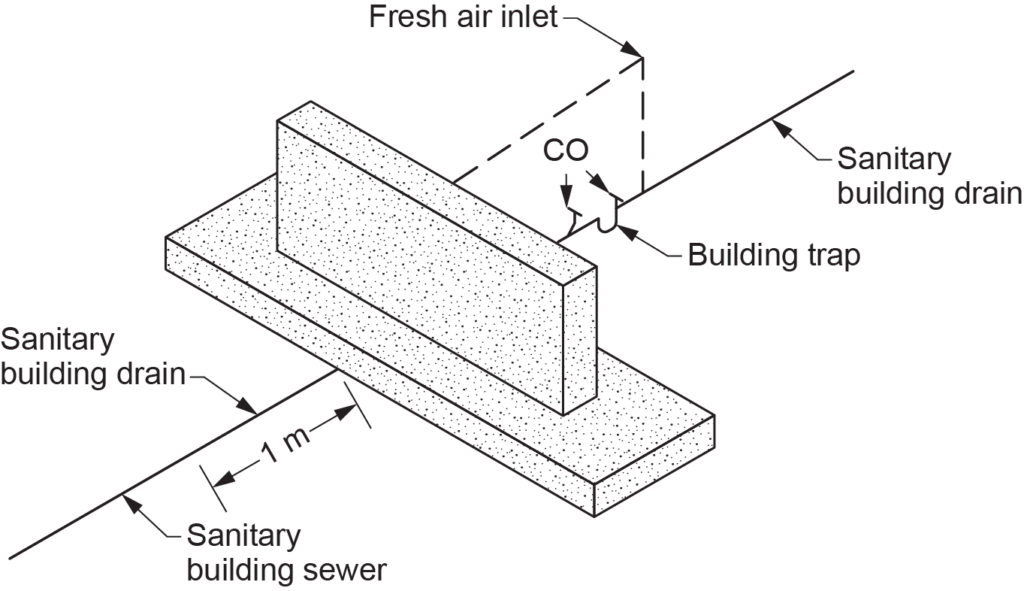

building sewer: a pipe that connects to a building drain 1 m (39 in.) outside the wall of a building and connects to a public sewer or private sewage disposal system (Figure 8).

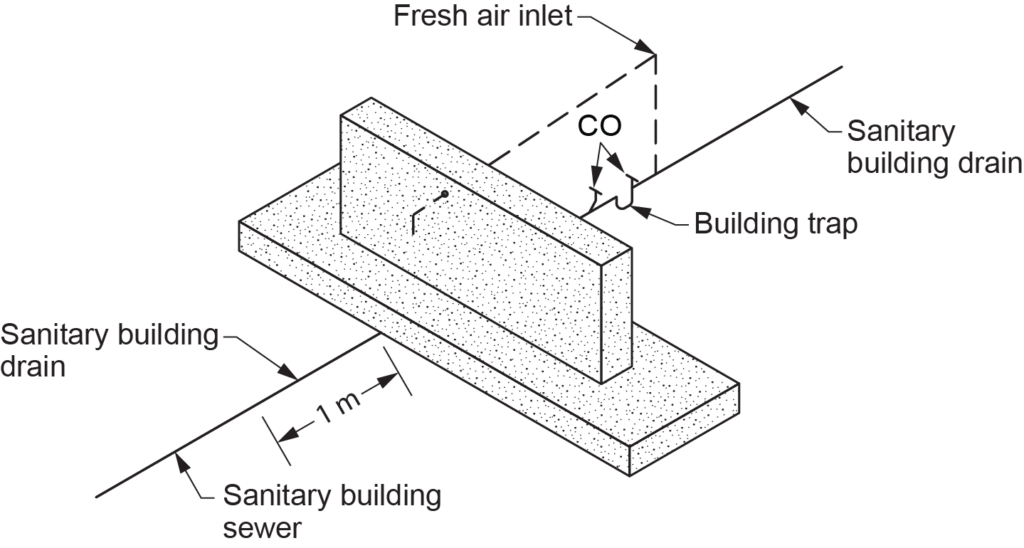

building trap: a trap installed in a building drain or building sewer to prevent the circulation of air between a drainage system and a public sewer. New buildings do not have building traps installed, but these traps still exist in older homes and buildings (Figure 9).

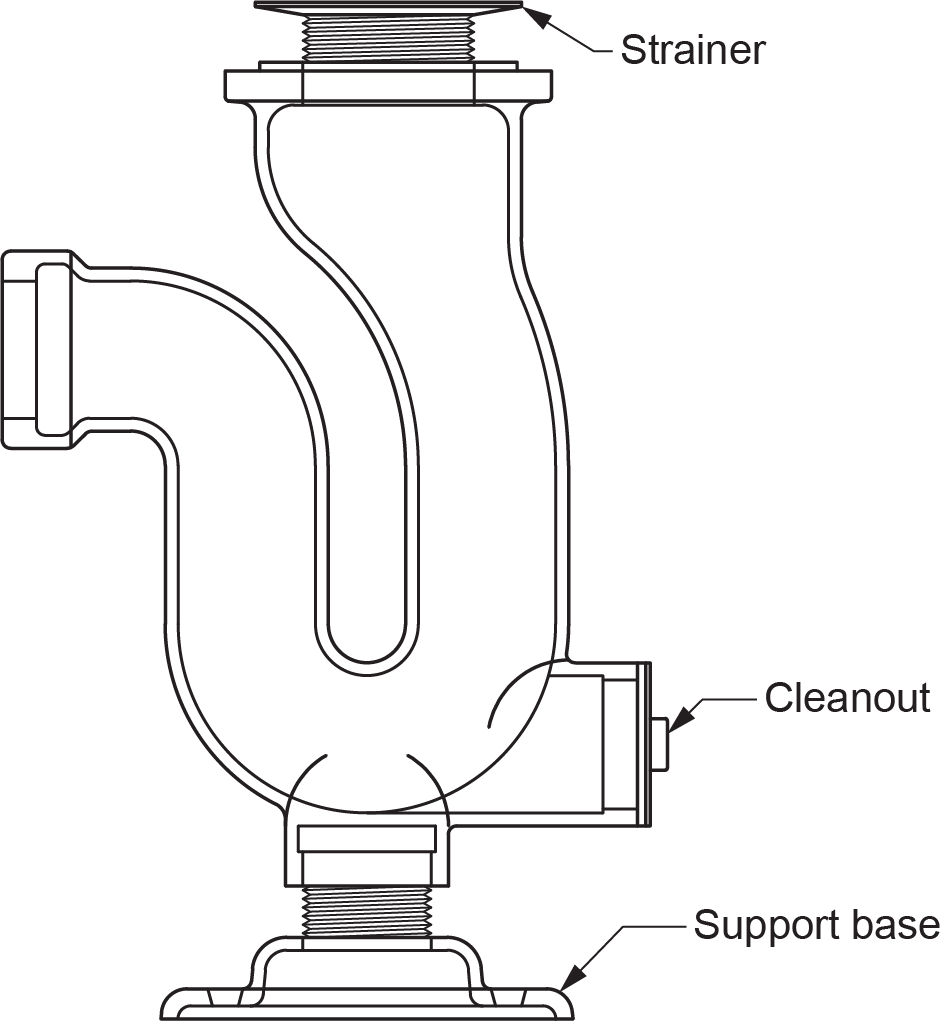

cleanout: an access point installed in drainage and venting systems for cleaning and inspection services.

clear-water waste: wastewater with impurity levels not harmful to health. It may include cooling water and condensate drainage from refrigeration and air-conditioning equipment and cooled condensate from steam heating systems, but it does not include stormwater.

combined building drain: a building drain intended to conduct sewage and stormwater (Figure 10).

combined building sewer: a building sewer intended to conduct sewage and stormwater.

combined sewer: a sewer intended to conduct sewage and stormwater.

continuous vent: a vent pipe that is an extension of a vertical section of a branch or fixture drain.

dead end: a pipe that terminates with a capped fitting.

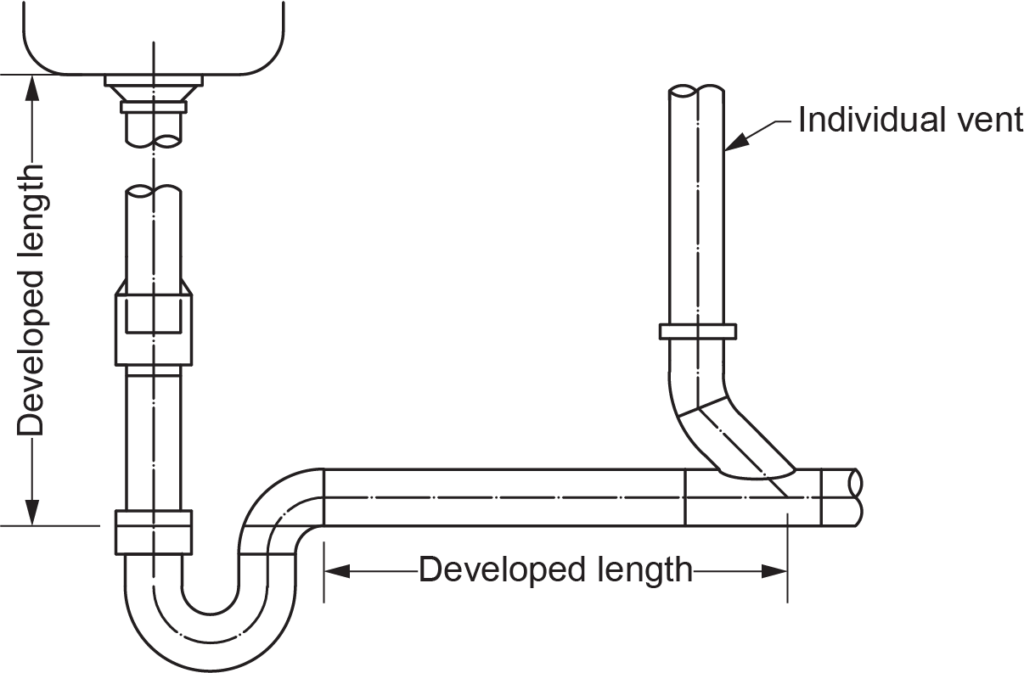

developed length: the length along the centreline of the pipe and fittings (Figure 12).

directly connected: implies that two pipes are physically connected in such a way that water or gas cannot escape from the connection.

drainage system: an assembly of pipes, fittings, fixtures, and traps used to convey sewage, clear-water waste, or stormwater to a public sewer or private sewage disposal system. It does not include subsoil drainage pipes.

dual vent: a vent pipe that serves two fixtures and connects at the junction of the trap arms (Figure 13).

emergency floor drain: a fixture used for overflow protection that does not receive regular discharge from other fixtures, other than from a trap primer. Any floor drain installed in a washroom is considered an emergency floor drain.

fixture: a receptacle, appliance, apparatus, or other device that discharges sewage or clear-water waste and includes a floor drain.

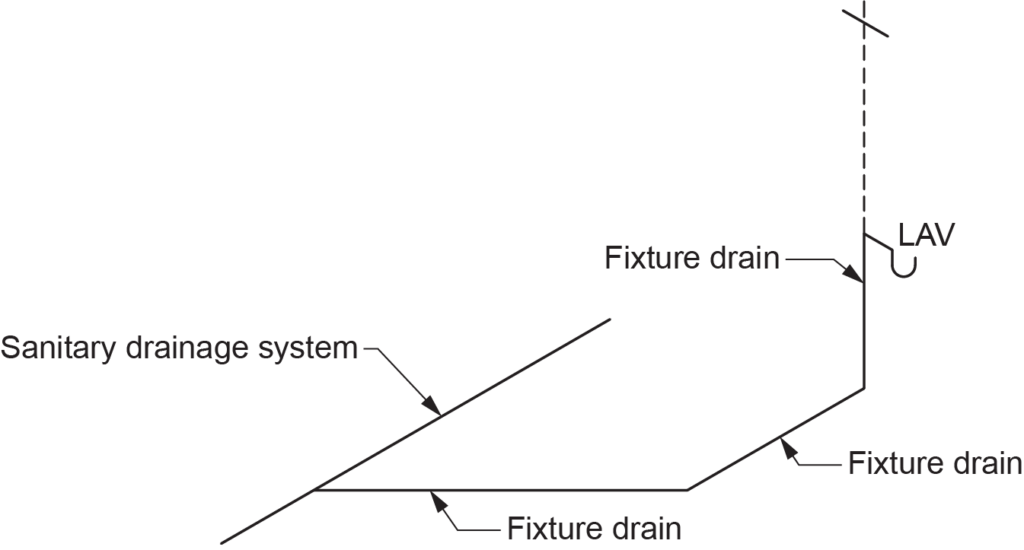

fixture drain: the pipe that connects a trap serving a fixture to another part of a drainage system (Figure 14).

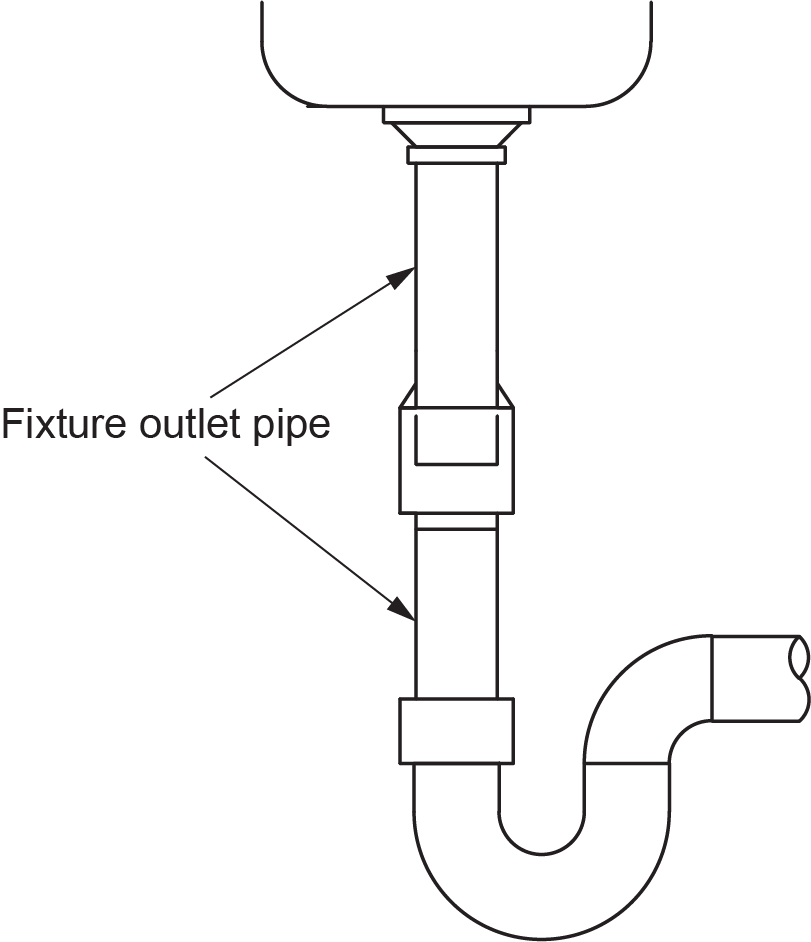

fixture outlet pipe: a pipe that connects the waste opening of a fixture to the inlet of the trap serving the fixture (Figure 15).

fixture unit (DWV): the unit of measure based on the rate of discharge, time of operation, and frequency of use of a fixture that expresses the hydraulic load imposed by that fixture on the drainage system.

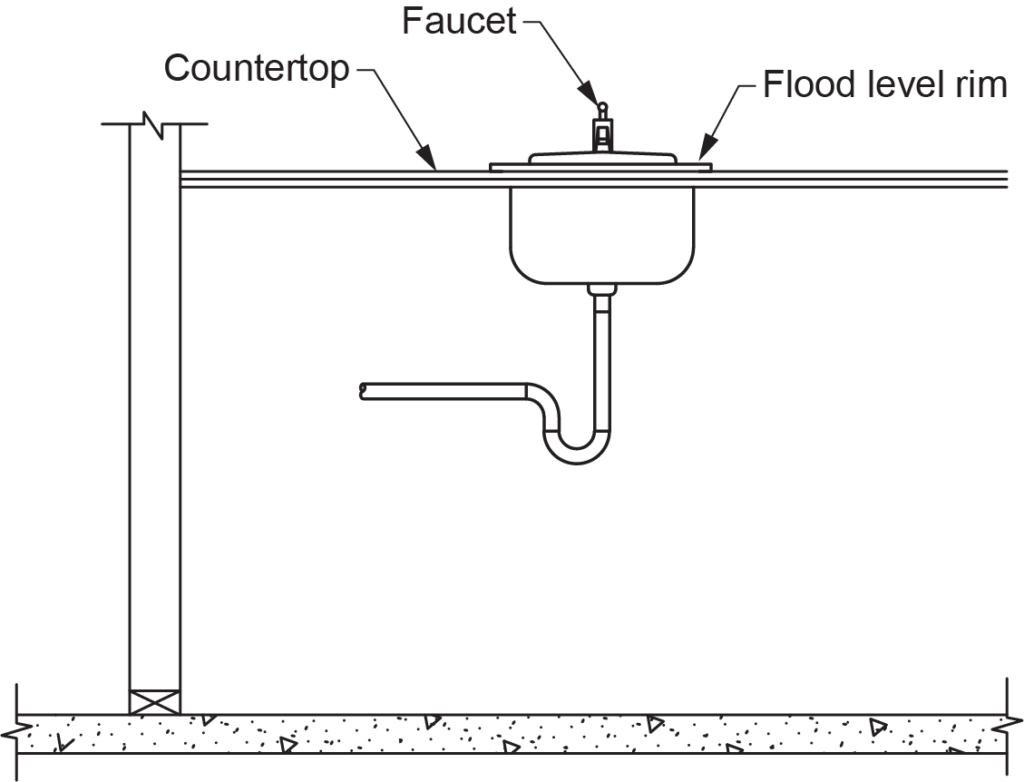

flood level rim: the top edge at which water can overflow from a fixture or device (Figure 16).

fresh air inlet: a vent pipe installed in conjunction with a building trap and that terminates outdoors. It is used to prevent an air lock between the fixture traps and the building trap by allowing air circulation through the DWV system (Figure 17).

indirectly connected: a pipe that does not connect directly with the drainage system but conveys liquid wastes by discharging into a plumbing fixture, interceptor, or receptacle directly connected to the drainage system. An air break separates the two systems. The air break prevents the possibility of wastes backing up into a compartment or device and contaminating it (Figure 18).

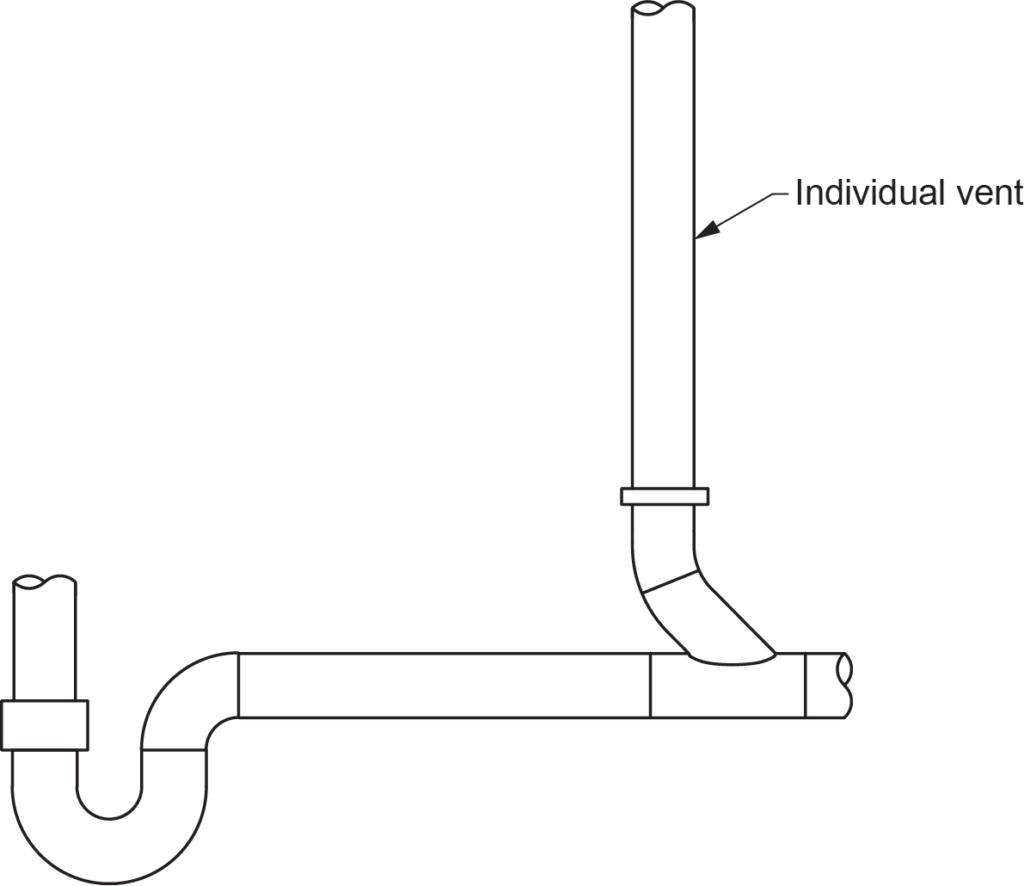

individual vent: a vent pipe that serves one fixture (Figure 19).

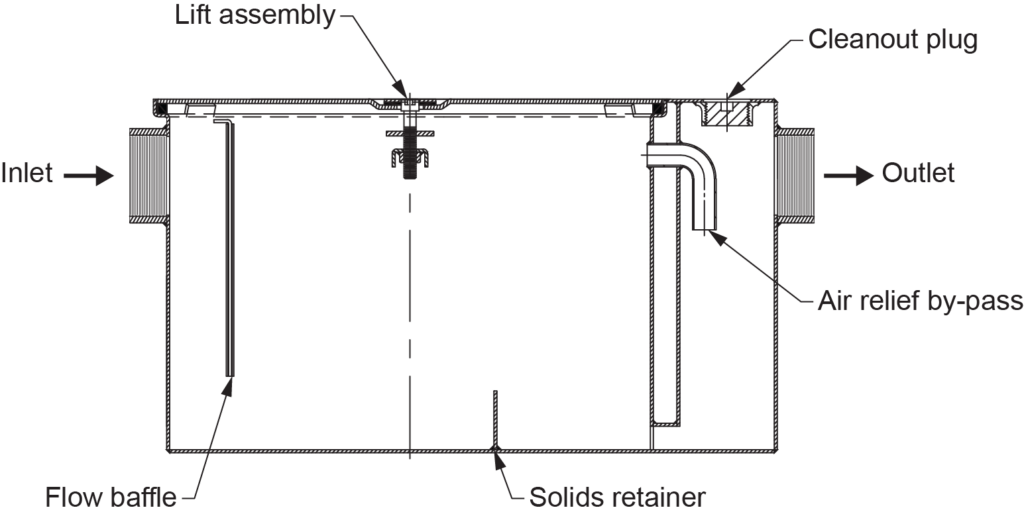

interceptor: a receptacle installed to prevent unwanted materials from passing into a drainage system. There are three main types of interceptors: grease, oil, and solids. Each of them requires different considerations for sizing, operation, and maintenance (Figure 20).

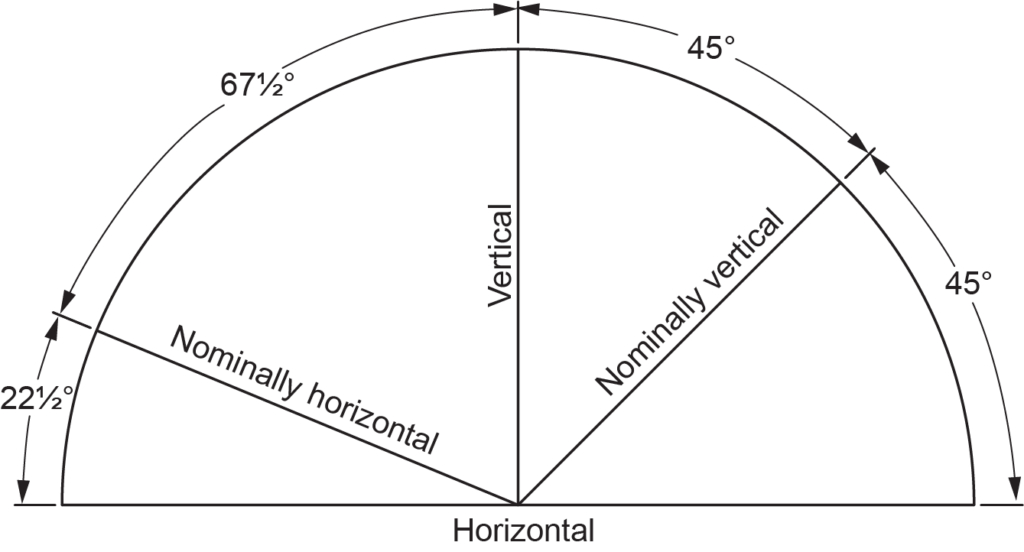

nominally horizontal: a DWV piping arrangement installed at an angle of less than 45° with the horizontal.

nominally vertical: a DWV piping arrangement installed at an angle of not more than 45° with the vertical (Figure 21).

nominal pipe size (NPS): the nominal diameter by which a pipe, fitting, trap, or other similar item is commercially designated.

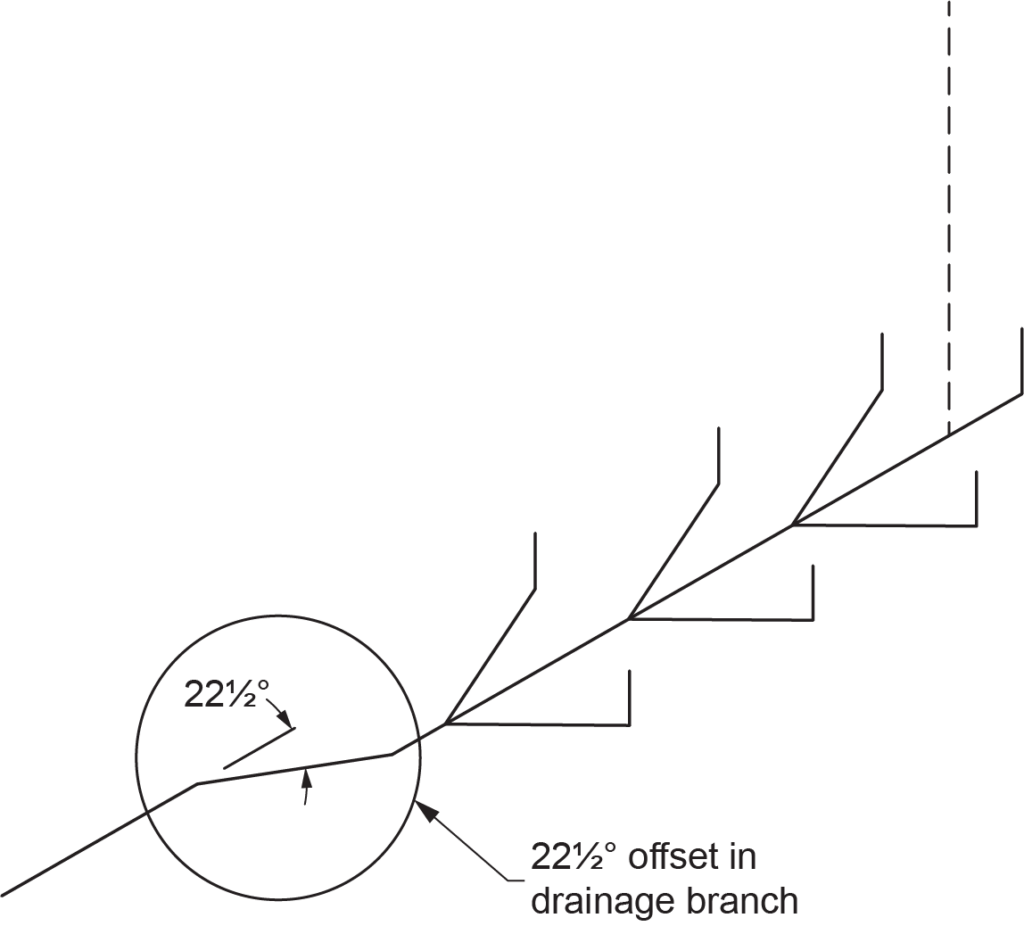

offset: the piping that connects the ends of two parallel pipes (Figure 22).

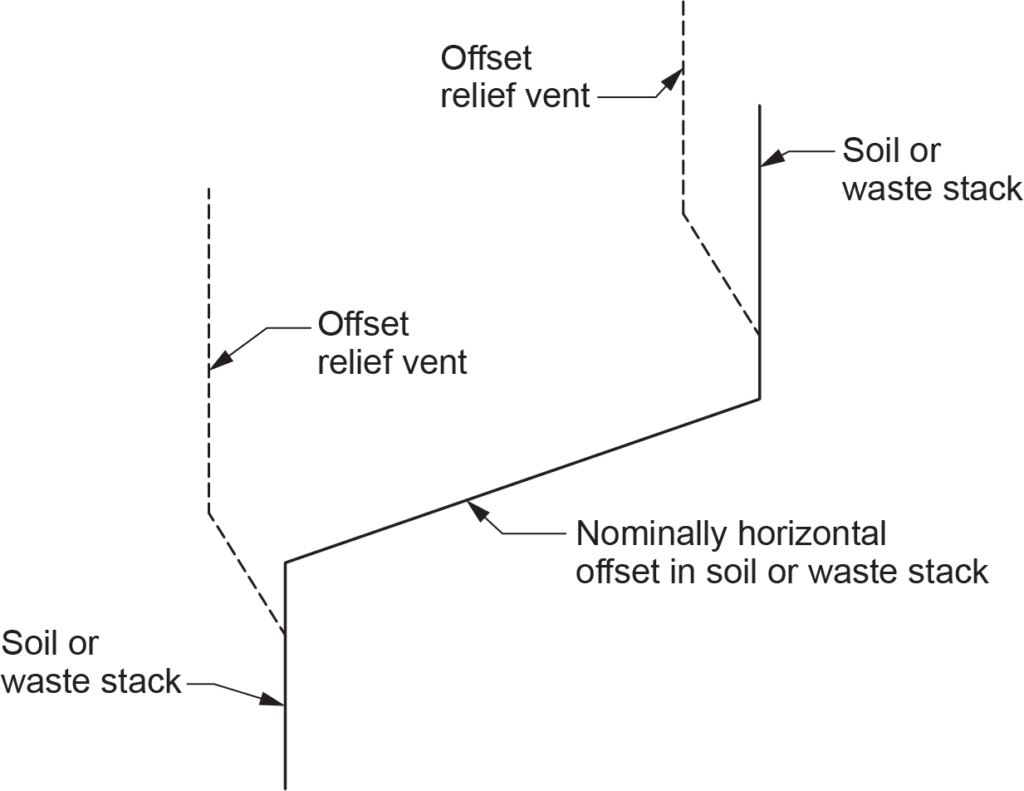

offset relief vent: a relief vent that provides additional air circulation upstream and downstream of an offset in a stack (Figure 23).

private sewage disposal system: a privately owned plant for treating and disposing of sewage (e.g., a septic tank with an absorption field).

private use (plumbing fixtures): fixtures in residences, apartments, or in private bathrooms of hotels or other buildings intended for use by one family or an individual.

public use (plumbing fixtures): fixtures that may be used by multiple users in a public setting, such as washrooms in schools, gymnasiums, hotels, bars, public comfort stations, and other installations where fixtures are installed so that their use is unrestricted.

relief vent: a vent pipe used in conjunction with a circuit vent to provide additional air circulation within a circuit-vented system (Figure 24).

sanitary building drain: a building drain that conducts sewage to a building sewer from the most upstream stack, branch, or fixture drain serving a water closet.

sanitary building sewer: a building sewer that conducts sewage (Figure 25).

sanitary drainage pipe: a pipe in a sanitary drainage system.

sanitary drainage system: a drainage system that conducts sewage.

sanitary sewer: a sewer that conducts sewage.

sewage: any liquid waste other than clear-water waste or stormwater.

stack: a vertical sanitary drainage pipe that passes through one or more storeys and includes any offset in the stack. Previously referred to as a soil-or-waste stack or SOWS.

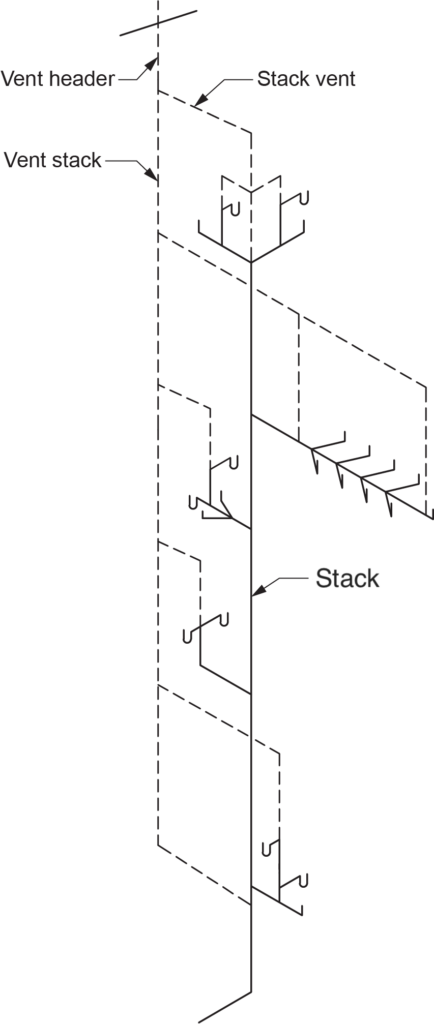

stack vent: a vent pipe that connects the top of a stack to a vent header or terminates to outside air (Figure 26).

storey (as applied to plumbing): the interval between two successive floor levels, including mezzanine floors that contain plumbing fixtures, or between a floor level and roof.

subsoil drainage pipe (drain tile/weeping tile): a pipe installed underground to intercept and convey subsurface water.

trap: a fitting or device designed to hold a liquid seal that prevents the passage of gas while allowing the flow of liquid to continue without significant obstruction.

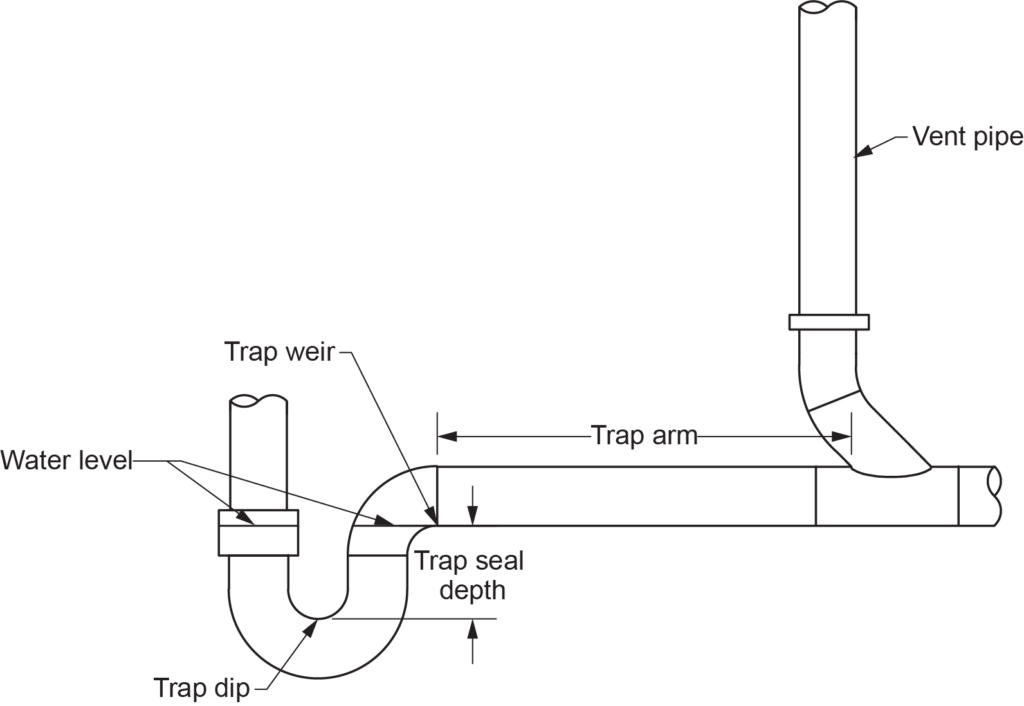

trap arm: the portion of a fixture drain between the trap weir and the vent pipe connection.

trap dip: the lowest part of the upper interior surface of a trap.

trap seal depth: the vertical distance between the trap dip and the trap weir.

trap weir: the highest part of the lower interior surface of a trap (Figure 27).

trap standard: a trap for a fixture that is integral to the support for the fixture (Figure 28).

vent header: a vent pipe that connects any combination of stack vents or vent stacks and terminates to outside air (Figure 29).

vent pipe: a pipe that is part of a venting system.

vent stack: a vent pipe that is connected at its upper end to a vent header or that terminates to outside air. It connects at its lower end to the stack at or below the lowest sanitary drainage pipe connection (Figure 30).

venting system: an assembly of pipes and fittings that connects a drainage system with outside air to circulate air and protect trap seals in the drainage system.

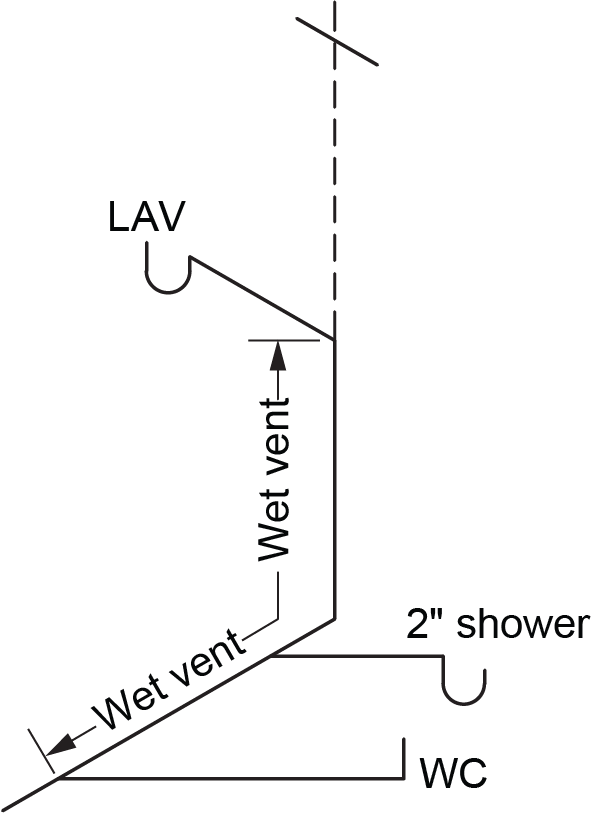

wet vent: a sanitary drainage pipe that also serves as a vent pipe and extends from the most downstream wet-vent fixture connection to the most upstream fixture dry-vent connection (Figure 31). A wet vent is a function of a branch, fixture drain, or stack and should be identified as a BR/WV, FD/WV, or a Stack/WV.

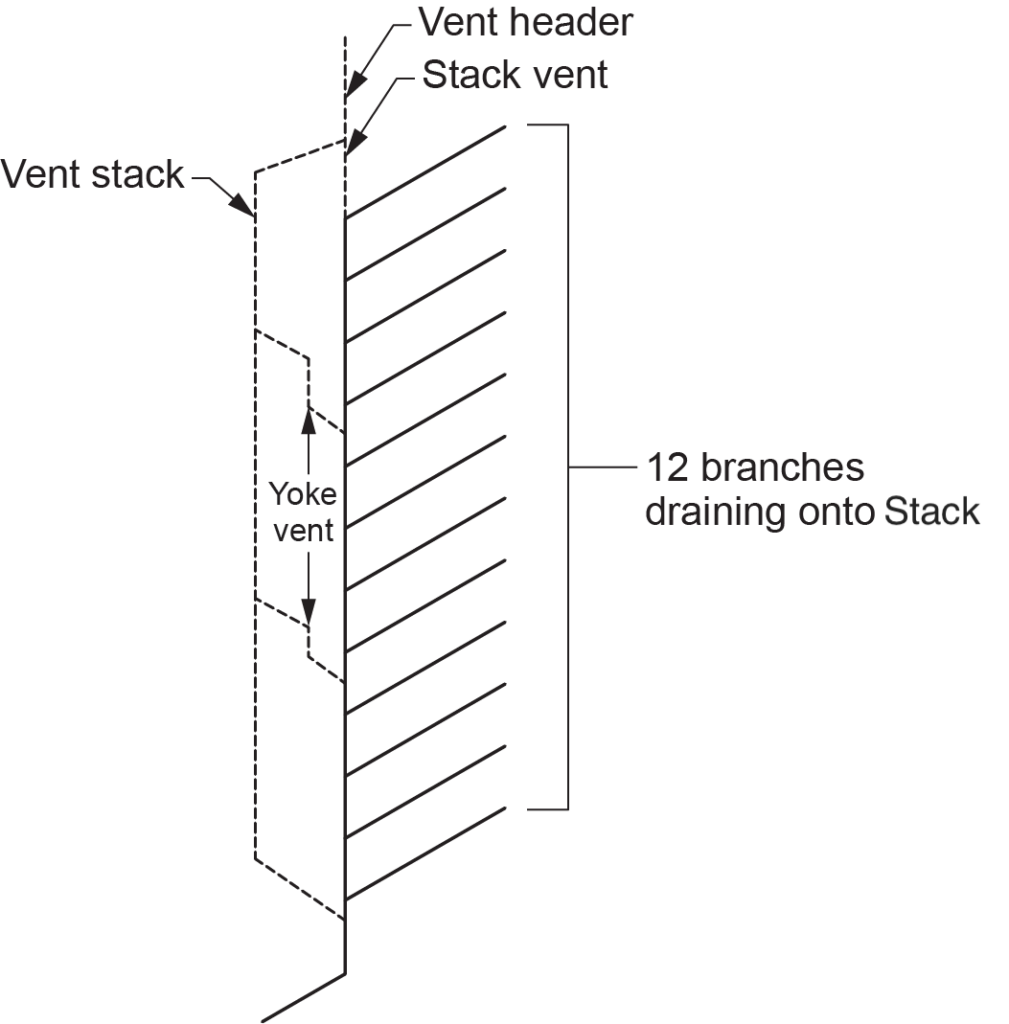

yoke vent: a vent pipe connected at its lower end to a stack and at its upper end to a vent stack or to a branch vent connected to a vent stack. A yoke vent is required when serving a stack receiving discharge from more than 11 storeys (Figure 32). A yoke vent provides extra air circulation for the operation of the stack.

Self-Test D-1.2: DWV Terminology

Self-Test D-1.2: DWV Terminology

Complete Self-Test D-1.2 and check your answers.

If you are using a printed copy, please find Self-Test D-1.2 and Answer Key at the end of this section. If you prefer, you can scan the QR code with your digital device to go directly to the interactive Self-Test.

References

National Research Council of Canada. (2020). National Plumbing Code of Canada 2020. Canadian Commission on Building and Fire Codes. https://nrc-publications.canada.ca/eng/view/ft/?id=6e7cabf5-d83e-4efd-9a1c-6515fc7cdc71

Skilled Trades BC. (2021). Book 2: Install fixtures and appliances, install sanitary and storm drainage systems. Plumber apprenticeship program level 2 book 2 (Harmonized). Crown Publications: King’s Printer for British Columbia.

Trades Training BC. (2021). D-1: Install sanitary drain, water and vent systems. In: Plumber Apprenticeship Program: Level 2. Industry Training Authority, BC.

Media Attributions

All figures are used with permission from Skilled Trades BC (2021) unless otherwise noted.

- Figure 11 Continuous vent is by TRU Open Press and can be used under the CC-BY-NC-SA license.

A vent pipe installed between a circuit vent and a relief vent to provide additional air circulation. (Figure 1, Section D-1.2)

Air admittance valves are mechanical devices that let air into the plumbing system to prevent siphoning while stopping air from escaping. They are used when traditional venting isn’t possible and should be installed in an accessible, ventilated area. (Figure 2, Section D-1.2)

An indirect connection between drainage pipes, created by a vertical gap of at least 25 mm (1 in.) to prevent contamination. It is commonly used for food prep sinks, drinking fountains, and ice makers. (Figure 3, Section D-1.2)

The governmental body responsible for enforcing any part of the NPC. (Section D-1.2; Section D-2.4)

A reversal of the normal direction of the flow. (Section D-1.2)

A group of plumbing fixtures installed in the same room, consisting of one domestic lavatory, one water closet, and either one bathtub (with or without a shower) or one single-head shower. The intent is that these three fixtures are located in a room occupied by only one person, so they are not normally in simultaneous use. (Section D-1.2)

A sanitary drainage pipe connected at its upstream end to the junction of two or more sanitary drainage pipes or to a stack and connected at its downstream end to another branch, a sump, a stack, or a building drain. (Figure 6, Section D-1.2)

A vent pipe connected at its lower end to the junction of two or more vent pipes. At its upper end, it either terminates in the open air or connects to another branch vent, stack vent, vent stack, or vent header. (Figure 7, Section D-1.2)

The lowest horizontal piping, including any vertical offset that conducts sewage, clear-water waste, or stormwater by gravity to a building sewer. (Figure 8, Section D-1.2)

A pipe that connects to a building drain 1 m (39 in.) outside the wall of a building and connects to a public sewer or private sewage disposal system. (Figure 8, Section D-1.2)

A trap installed in a building drain or building sewer to prevent the circulation of air between a drainage system and a public sewer. New buildings do not have building traps installed, but these traps still exist in older homes and buildings. (Figure 9, Section D-1.2)

Wastewater with impurity levels not harmful to health. It may include cooling water and condensate drainage from refrigeration and air-conditioning equipment and cooled condensate from steam heating systems, but it does not include stormwater. (Section D-1.2; Section D-3.1)

A building drain intended to conduct sewage and stormwater. (Figure 10, Section D-1.2; Section D-3.1)

A sewer intended to conduct sewage and stormwater. (Section D-1.2; Section D-3.1)

A vent pipe that is an extension of a vertical section of a branch or fixture drain. (Section D-1.2)

A pipe that terminates with a capped fitting. (Section D-1.2)

The length along the centreline of the pipe and fittings. (Figure 12, Section D-1.2)

Implies that two pipes are physically connected in such a way that water or gas cannot escape from the connection. (Section D-1.2)

An assembly of pipes, fittings, fixtures, and traps used to convey sewage, clear-water waste, or stormwater to a public sewer or private sewage disposal system. It does not include subsoil drainage pipes. (Section D-1.1; Section D-1.2)

A vent pipe that serves two fixtures and connects at the junction of the trap arms. (Figure 13, Section D-1.2)

A fixture used for overflow protection that does not receive regular discharge from other fixtures, other than from a trap primer. Any floor drain installed in a washroom is considered an emergency floor drain. (Section D-1.2)

A receptacle, appliance, apparatus, or other device that discharges sewage or clear-water waste and includes a floor drain. (Section D-1.2; Section D-2.3)

The pipe that connects a trap serving a fixture to another part of a drainage system. (Figure 14, Section D-1.2)

A pipe that connects the waste opening of a fixture to the inlet of the trap serving the fixture. (Figure 15, Section D-1.2)

The unit of measure based on the rate of discharge, time of operation, and frequency of use of a fixture that expresses the hydraulic load imposed by that fixture on the drainage system. (Section D-1.2)

The top edge at which water can overflow from a fixture or device. (Figure 16, Section D-1.2)

A vent pipe installed in conjunction with a building trap and that terminates outdoors. It is used to prevent an air lock between the fixture traps and the building trap by allowing air circulation through the DWV system. (Figure 17, Section D-1.2)

A pipe that does not connect directly with the drainage system but conveys liquid wastes by discharging into a plumbing fixture, interceptor, or receptacle directly connected to the drainage system. An air break separates the two systems. The air break prevents the possibility of wastes backing up into a compartment or device and contaminating it. (Figure 18, Section D-1.2)

A vent pipe that serves one fixture. (Figure 19, Section D-1.2)

A receptacle installed to prevent unwanted materials from passing into a drainage system. There are three main types of interceptors: grease, oil, and solids. Each of them requires different considerations for sizing, operation, and maintenance. (Figure 20, Section D-1.2; Section D-1.11)

A DWV piping arrangement installed at an angle of less than 45° with the horizontal. (Figure 21, Section D-1.2)

A DWV piping arrangement installed at an angle of not more than 45° with the vertical. (Figure 21, Section D-1.2)

The nominal diameter by which a pipe, fitting, trap, or other similar item is commercially designated. (Section D-1.2)

The piping that connects the ends of two parallel pipes. (Figure 22, Section D-1.2)

A relief vent that provides additional air circulation upstream and downstream of an offset in a stack. (Figure 23, Section D-1.2)

A privately owned plant for treating and disposing of sewage (e.g., a septic tank with an absorption field). (Section D-1.2)

Fixtures in residences, apartments, or in private bathrooms of hotels or other buildings intended for use by one family or an individual. (Section D-1.2)

Fixtures that may be used by multiple users in a public setting, such as washrooms in schools, gymnasiums, hotels, bars, public comfort stations, and other installations where fixtures are installed so that their use is unrestricted. (Section D-1.2)

A vent pipe used in conjunction with a circuit vent to provide additional air circulation within a circuit-vented system. (Figure 24, Section D-1.2)

A building drain that conducts sewage to a building sewer from the most upstream stack, branch, or fixture drain serving a water closet. (Section D-1.2; Section D-1.3)

A building sewer that conducts sewage. (Figure 25, Section D-1.2)

A pipe in a sanitary drainage system. (Section D-1.2)

A drainage system that conducts sewage. (Section D-1.2)

The main underground pipe that carries wastewater out of a building. (Section D-1.2; Section D-2.3)

Any liquid waste other than clear-water waste or stormwater. (Section D-1.2)

A vertical sanitary drainage pipe that passes through one or more storeys and includes any offset in the stack. Previously referred to as a soil-or-waste stack or SOWS. (Section D-1.2; Section D-2.3)

A vent pipe that connects the top of a stack to a vent header or terminates to outside air. (Figure 26, Section D-1.2)

The interval between two successive floor levels, including mezzanine floors that contain plumbing fixtures, or between a floor level and roof. (Section D-1.2)

A pipe installed underground to intercept and convey subsurface water. (Section D-1.2)

A fitting or device designed to hold a liquid seal that prevents the passage of gas while allowing the flow of liquid to continue without significant obstruction. (Section D-1.2)

The portion of a fixture drain between the trap weir and the vent pipe connection. (Section D-1.2; Section D-1.3)

The lowest part of the upper interior surface of a trap. (Section D-1.2)

the vertical distance between the trap dip and the trap weir. (Section D-1.2)

The highest part of the lower interior surface of a trap. (Figure 27, Section D-1.2)

A trap for a fixture that is integral to the support for the fixture (Figure 28, Section D-1.2)

A vent pipe that connects any combination of stack vents or vent stacks and terminates to outside air. (Figure 29, Section D-1.2)

A pipe that is part of a venting system. (Section D-1.2)

A vent pipe that is connected at its upper end to a vent header or that terminates to outside air. It connects at its lower end to the stack at or below the lowest sanitary drainage pipe connection (Figure 30, Section D-1.2).

An assembly of pipes and fittings that connects a drainage system with outside air to circulate air and protect trap seals in the drainage system. (Section D-1.1; Section D-1.2)

A sanitary drainage pipe that also serves as a vent pipe and extends from the most downstream wet-vent fixture connection to the most upstream fixture dry-vent connection (Figure 31). A wet vent is a function of a branch, fixture drain, or stack and should be identified as a BR/WV, FD/WV, or a Stack/WV. (Section D-1.2)

A vent pipe connected at its lower end to a stack and at its upper end to a vent stack or to a branch vent connected to a vent stack. A yoke vent is required when serving a stack receiving discharge from more than 11 storeys (Figure 32). A yoke vent provides extra air circulation for the operation of the stack. (Section D-1.2)