D-5.1 Drain Cleaning

Safety Precautions When Drain Cleaning

Using drain-cleaning equipment safely and effectively requires service personnel to wear personal protective equipment (PPE) while working on sewer or drain lines. Two important safety items essential to drain cleaning are:

- Safety glasses or goggles with side shields

- Gloves

Eye protection is an important safeguard against flying solid objects or pathogenic liquids, which can become airborne when, for instance, the tension on a cable is suddenly released. Gloves protect a technician’s hands from sharp objects and are especially important for the hand that guides the cable into and out of the drain. The sudden release of a stoppage can cause the cable to spin rapidly enough to burn or cut bare hands.

Drains and sewers can carry bacteria and other infectious micro-organisms or materials that can cause death or severe illness. Avoid exposing eyes, nose, mouth, ears, hands, cuts, and abrasions to wastewater or other potentially infectious materials during drain and sewer cleaning operations.

Service personnel also need to be aware of the risks presented by ponding water from backed-up drains. One good safety practice is to stand on boards or a solid pallet to prevent electrical shock from grounding through water. As with any power tool, always check the safety features provided by the manufacturer before taking the equipment to the job site.

Since drain cleaners can suddenly hit blocks or stoppages, you should never force them through the blockage. The best practice is to use short forward and reverse movements of the cable to prevent jamming and breakage.

The cable drum should be cleaned before it is returned to storage because bacteria and pathogens can be transferred during handling, even after the job has been completed.

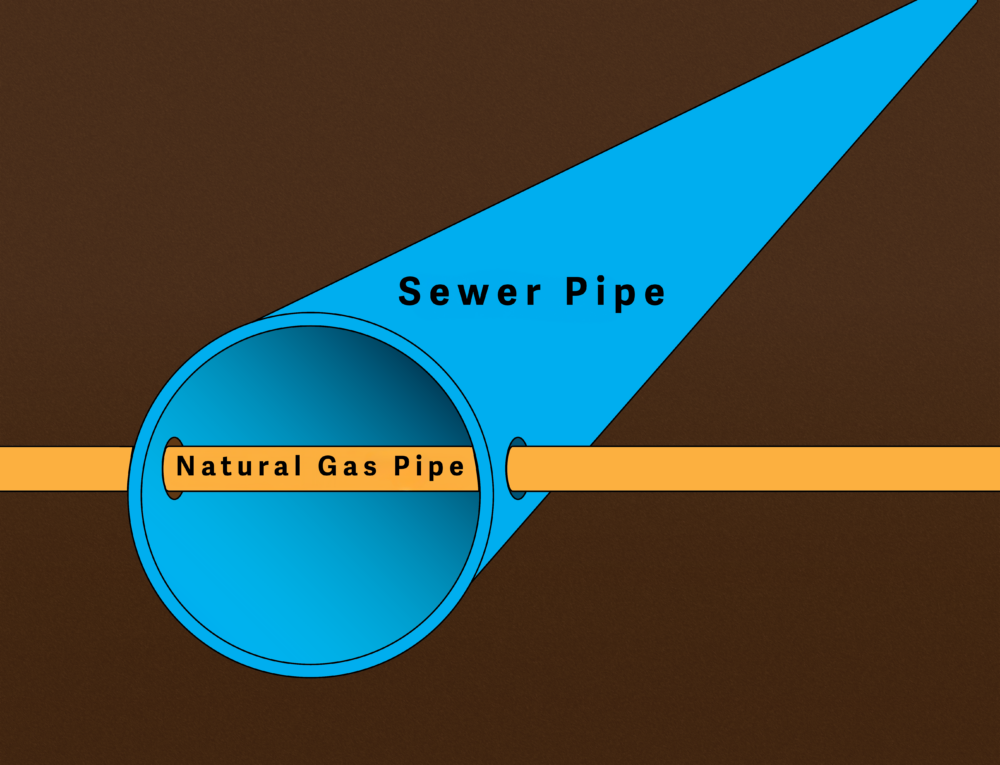

Cross Bores

To help minimize sidewalk and landscaping damage, new service lines — such as gas, electric, and cable TV — are usually installed by drilling holes horizontally beneath the ground. A “cross bore” is when the new pipe or cable accidentally goes through another underground pipe or cable (Figure 1).

A clogged sewer line may result from a cross bore with a gas line. Many explosions and deaths have occurred when a drain auger has ripped through a plastic gas line that has been drilled through a building sewer and caused a blockage.

A drain auger — when sent down the sewer to clear a blockage often thought to have been caused by root penetration — will easily tear through the HDPE line, causing high-pressure gas to exit the sewer downstream of that point as well as upstream toward the auger’s operator. Fires and explosions are the most common result, with property damage being the least of the outcomes.

Before clearing and underground drains, you should:

- Look for trees or landscaping that could possibly be causing an obstruction.

- Ask the resident if there has been any recent utility work in the area.

- Use an in-line video inspection device to better assess the blockage.

During the cleaning, you should:

- Clear without a cutting tool. Use minimally invasive equipment, such as a plumbing snake or water jet, to attempt to clear the blockage.

- Feel for obstructions that do not seem to resemble tree roots or other common obstructions as the tool moves through the sewer line.

After you finish, you should:

- Check the blades for yellow or orange plastic when it is withdrawn from the sewer line. Natural gas utility lines are typically made of these colours of plastic.

- Watch for bubbles caused by natural gas escaping from the toilet or other entry point of the cutting equipment. If bubbles or gas are found to be escaping from the entry point of the cutting equipment, IMMEDIATELY exit the structure. In such cases, warn all inhabitants as well.

- Inspect the area with a Combustible Gas Indicator (CGI) or other gas-detection equipment, if available.

Video Inspection Equipment

Video inspection equipment uses a remote video camera to inspect underground sewers and drains. If a stoppage is due to a suspected cross bore, video inspection should be attempted first; however, the video image is rarely of good quality when viewing through the sludge at a blockage. If determined to be safe to do so, the drain is typically cleared first using a cleaning auger before being visually inspected.

A video inspection provides an excellent way to detect and locate obstructions or damage that impedes or stops the flow of drainage lines. Video inspections can detect common problems such as:

- Root-bound drainage lines

- Pipe collapse and cracks

- Running inline traps

- Negative grade sloping

- Pipe sagging

- Offset joints

- Sludge buildup

The video camera equipped with LED lighting is “pushed” down the drain or sewer line from a reel on the surface that is connected to a recording monitor (Figure 2). The plumber receives the closed-circuit live picture and views it on a monitor as the video records to a flash drive or DVD archive for future reference.

Pipe Locators

On some models of video inspection equipment, the camera is equipped with a radio transmitter (Figure 3). The camera/transmitter assembly sends a signal to a receiver on the ground surface indicating the camera location and depth of burial. This information can be vital if the line has to be excavated and repaired.

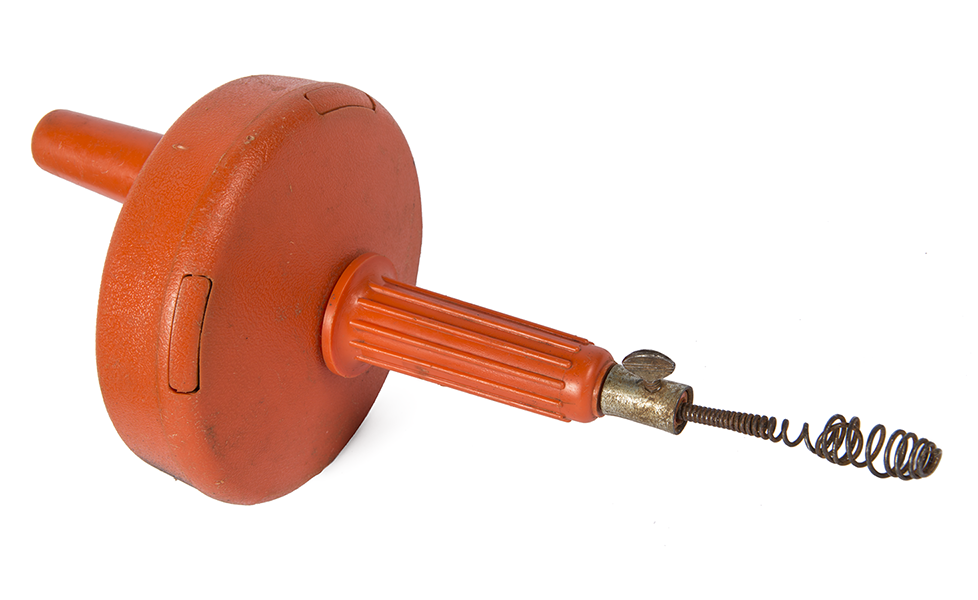

Drain Augers

A drain auger is typically a long, flexible metal cable that rotates in a circular motion and is powered by an electric motor or by hand. On some models, the tool that attaches to the end can be changed to meet specific job requirements. The drain auger is inserted into a drain and rotated until it reaches the obstruction. The auger then breaks through and retrieves or reduces the obstruction so the drain can flow freely.

There are several different types of drain augers for home and commercial use:

- Hand auger

- Closet auger

- Power drum auger for small-diameter piping

- Power drum auger for large-diameter piping

Hand Auger

The hand auger uses a drum to contain the cable and keep it from tangling and kinking while being rotated by hand (Figure 4). These tools are useful for clearing small-diameter sink and bathtub drains (up to 2 in. NPS) when the obstruction has yet to solidify. Do not attempt to send this auger through toilet bowls because the exposed wire cable might damage the porcelain finish. Also, due to the large bowl passageway and the cable’s small diameter, the cable can become tangled when rotated.

Some hand augers can be attached to an electric drill, giving it more power to force it through the clog while also making it easier for the operator to use (Figure 5).

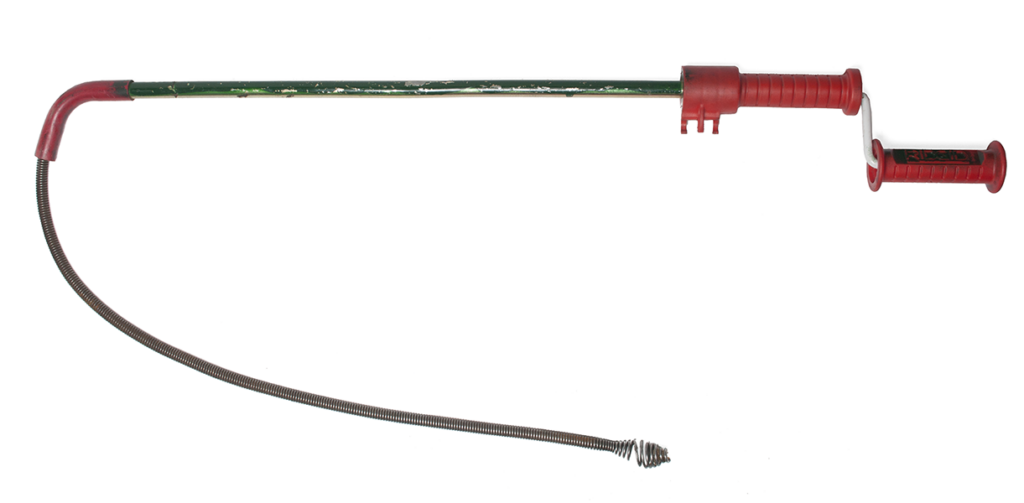

Closet Auger

The closet auger, named after the water closet, feeds a relatively short cable through a hook-shaped length of metal tubing (Figure 6). The hook shape makes it easier to feed the cable into a toilet. A plastic boot on the end of the cable protects the finish of the visible porcelain. Since most toilet clogs occur in the integral trap, the short cable is sufficient to break up or retrieve most clogs.

Power Drum Augers (Small-Diametre Piping)

This power auger consists of a drum containing a length of cable (15 m/50 ft of [latex]\tfrac{1}{4}[/latex] in. or [latex]\tfrac{5}{16}[/latex] in. or 10 m/35 ft of [latex]\tfrac{3}{8}[/latex] in.) that is generally mounted on the end of a variable-speed electric drill. This hand-held drain cleaner can clear clogs in lines from 32 mm to 75 mm ([latex]1\tfrac{1}{4}[/latex] in.–3 in.) in diameter in awkward and tight spaces. The motor also has a quick-reversing switch to help release the cable should it get caught in a drain line.

The rotation of the drill unspools and drives the cable down a pipe. The cable is gripped by a chuck that must be loosened by hand for the cable to be loosened and manually fed into the drain and must again be hand-tightened to lock the cable in place. When the cable reaches the clog, the tip begins digging into and loosening the material.

This is where an electric power drum auger offers many benefits over a manual version. Using a hand auger, you are limited to the power you can generate and maintain with your hands alone. With a power auger, you can slowly ease up the pressure you are applying to a clogged drain in order to more effectively get rid of the obstruction.

Power Drum Augers (Large-Diametre Piping)

This power tool consists of a cable 30 m (100 ft) — or sometimes 15 m (50 ft) — long wrapped inside a metal drum or cage-like spool, which is turned by a reversible electric motor (Figure 7). Long lengths of cable contained within a cage or drum are not the only variety of cable available. Some models of drain augers use 8 ft (2.4 m) sections of cable in straight lengths that are fed through the machine and coupled using male and female ends before feeding again.

These tools are incredibly powerful, using low internal gear ratios to move slowly but with enough force to break apart or cut tough material. These machines are too heavy for one person to carry, so they are typically equipped with a frame with two wheels, allowing it to be rolled around like a dolly.

To use this type of tool, position the auger a few feet away from the cleanout and plug its power cord into a nearby grounded electrical outlet. Most augers have a foot pedal that allows the motor to be controlled hands-free. Set this down in a convenient location. Pull out the cable and feed it into the pipe a few feet, then press the pedal to start spinning the cable (and cutter head) in the normal (clockwise) rotation. While the auger is spinning, pull the cable off the spool and feed it into the drain a foot or so at a time. In addition to powering the cutting action, the rotation helps the cable work its way through bends in the drain pipe.

If the cable meets resistance, it could be an offset or obstruction. In either case, do not try to force the cable forward. Back off the cutter head by retracting the cable a bit, then feed it in again.

When the cutter encounters an obstruction, it may grab the material and stop turning while the cable keeps spinning. The cable is actually a tightly wound torsion spring, so you can let it wind up for a few rotations, but going too far can break it. Let the energy build up a little bit, then pull the cable back to free the cutter blade; the cable will instantly spin back to its normal position.

If the cutter gets stuck and you cannot get the cable unwound, stop the auger rotation, hit the reverse switch on the motor, and rotate the auger backward. Then, pull the cutter free before resuming in the clockwise rotation.

Once the cable returns to the normal position, start feeding it in again. Repeat the process until the drain is clear. Often, it is necessary to pull the cable all the way back out to check the cutter head for roots and other debris.

Advantages of electric drain cleaners include the ability to clean long sections of sewer drain and the ability to remove solid objects, such as tree roots. Machines using flexible attachments can easily negotiate multiple 90° bends while maintaining their effectiveness and without damaging the pipe.

Safety considerations for electric drain cleaners include the following:

- Wear work gloves and eye protection.

- Carefully control the cable during operation to avoid over-stressing it.

- Use appropriate caution when working around rotating machinery.

- Use properly grounded electrical outlets.

Auger Heads

Large-diameter machines typically have interchangeable heads that can be attached to the cable, each suited to a specific task. The most common types of auger heads are:

- Drop head auger

- Straight auger

- Funnel auger

- Hook auger

- Retrieving auger

- Spade cutter

- Four-blade sawtooth cutter

- Grease cutter

- Spiral sawtooth cutter

- Sawtooth cutter

- Spiral bar cutter

- Sharktooth cutter

- Grease C cutter

- Expanding finish cutter

- Chain knocker

Drop head auger: for cleaning the trap arms of fixtures mounted back-to-back (e.g., sinks where cable needs to be led into downpipe) (Figure 8).

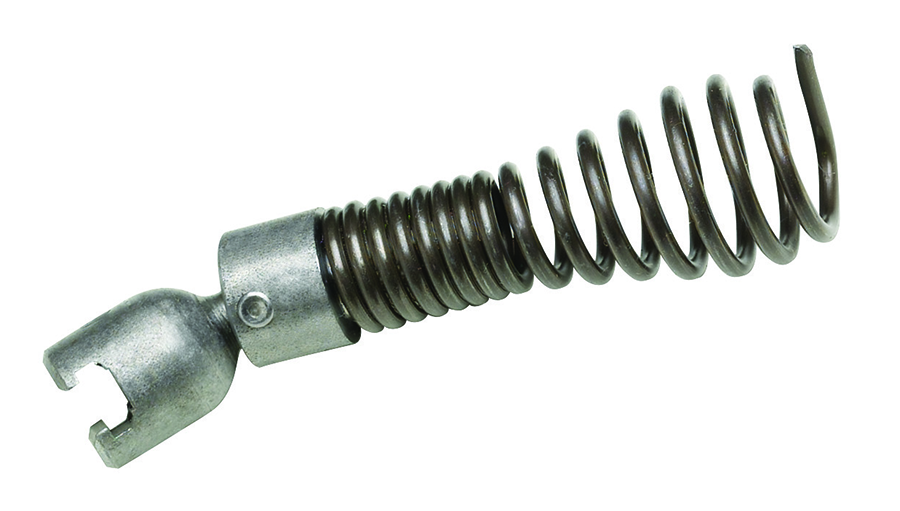

Straight auger: for use in exploring and breaking up stoppages or returning samples to the surface to determine the correct tool to use (Figure 9).

Funnel auger: for use as a second tool in line. It breaks up the stoppage remains left by a straight auger (Figure 10).

Hook auger: for heavy and dense root stoppages in pipes that require hooking into and breaking up (Figure 11).

Retrieving auger: used for searching for cable that is broken or lost in a drain line (Figure 12).

Spade cutter: for following up after augers have been used and to open up floor drains (Figure 13).

Four-blade sawtooth cutter: for blockages caused by hardened, glazed material, such as chemical deposits (Figure 14).

Grease cutter: for lines that have become badly clogged with grease or detergents and have to be opened (Figure 15).

Spiral sawtooth cutter: for clearing any stoppage caused by roots, rags, sticks, etc. (Figure 16).

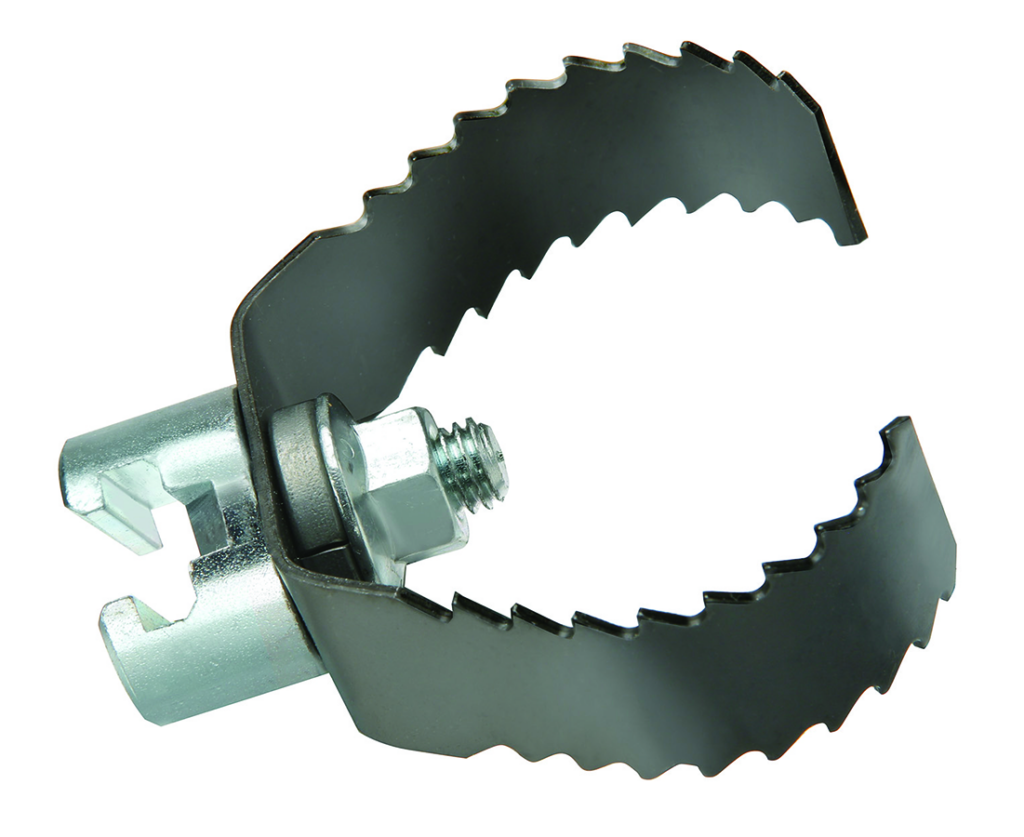

Sawtooth cutter: for cleaning lines blocked heavily with roots. Its unique design permits the cutter to be removed from damaged pipe without locking (Figure 17).

Spiral bar cutter: for main sewers blocked by roots, leaf debris, sticks, sawdust, cloth, or sack material (Figure 18).

Sharktooth cutter: for use in cleaning pipes of general material clinging to pipe walls (Figure 19).

Grease C cutter: For grease blockages in lines leading from garbage disposal units or waste pipes (Figure 20).

Expanding finish cutters: for final removal of material adhering to walls and certain roots of fibrous nature (Figure 21).

Chain knocker: for use when vigorous action is required to clean scale in pipes and boiler tubes (Figure 22).

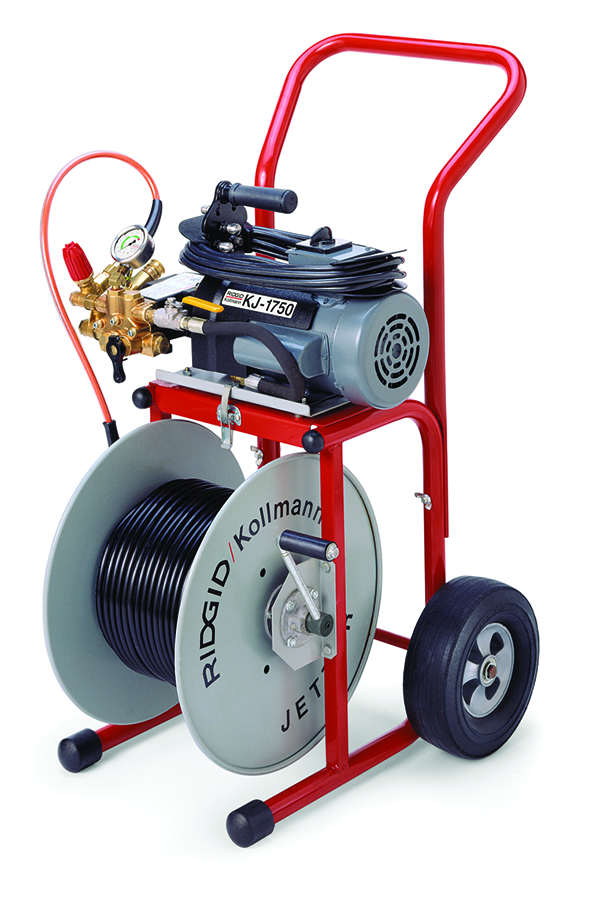

Water jetting is a method of cleaning or unclogging drains and sewers using high-pressure water to remove debris. High-pressure water jetters usually operate with water pressures up to 28,000 kPa (4,000 psig), with flow rates of 9 to 113 L (2 to 25 gal.) of water per minute.

The pressure of the water jet propels a highly flexible hose through lines measuring 32 to 100 mm (1[latex]\tfrac{1}{4}[/latex] in. to 4 in.), blasting through sludge, soap, and grease blockages. As you pull the hose back, it power-scrubs the line, flushing debris away and restoring drain lines to their free-flowing capacity. By introducing water into an already plugged line, the drainage pipe is ideally cleaned from the downstream end of the pipe, and the hose propels itself upstream.

When it is impossible to clean from the lower end of the pipe, the pipe must be water jetted several times to remove all the debris.

Water jetters can be truck-mounted and may carry up to 6,800 L (1,500 gal.) of water for large sewer cleaning jobs, or they can be mounted on a trailer and pulled by a large van or small truck. Smaller water jetters can be mounted on a cart for residential and light commercial applications (Figure 23).

When using this type of tool for a residential job, be aware of any cross-contamination issues. If a direct connection from the building’s houseline is used, there must be an approved backflow preventer in the form of an RPBA (reduced pressure backflow assembly) installed between the houseline and the jetter.

Air Blasters

Air blaster drain cleaners use accelerated carbon dioxide, air, or other gas to rupture the obstruction membrane. Accelerated gas creates a force on standing water that can dislodge clogs that accumulate close to drain openings but are too far away from the drain opening to be removed with a plunger. Unlike drain augers, air blasters do not pose any risk of scratching the surfaces of ceramic sinks, bathtubs, and toilets.

Disadvantages of air blaster drain cleaners include a limited cleaning range in pipes that do not contain standing water and, in general, ineffectiveness for unclogging blocked main sewer drains. Air blasters can also force air and water back through the overflow of a basin if used improperly.

Safety considerations for air blaster drain cleaners include a requirement to wear eye protection and, when using an air-burst cleaner that uses compressed gas cartridges, careful handling of unused cartridges.

Steam Cleaning

Unlike air- and water jet systems, steam cleaning is an entirely different process. The steam cleaner (Figure 24) uses steam’s expansion to accelerate water droplets, at the boiling point, to a high velocity. The closer the steam cleaner’s nozzle is to the surface to be cleaned, the higher the temperature and velocity of the water/steam mixture, and the more rapid the cleaning action. The temperature of the water/steam mixture drops quickly as the distance between the nozzle and the surface to be cleaned increases.

Consequently, for drain-cleaning applications, the nozzle should be held close to the inner surfaces to achieve the best results.

Shop Vacuum

Most “shop vacs” have an output blower mode that should be powerful enough to clear small drain obstructions. Place the end of the vacuum hose firmly over the drain and seal the edges to maintain output pressure. Make sure any other drain openings are closed or tightly plugged.

In blower mode, quickly turn the power on and off repeatedly until you dislodge the clog from the drain. Continuously running the blower for a long period of time can damage your pipes (or the vacuum, if its air flow is restricted).

Self-Test D-5.1: Drain Cleaning

Self-Test D-5.1: Drain Cleaning

Complete Self-Test D-5.1 and check your answers.

If you are using a printed copy, please find Self-Test D-5.1 and Answer Key at the end of this section. If you prefer, you can scan the QR code with your digital device to go directly to the interactive Self-Test.

References

RIDGID. (n.d.). Sectional cable tools [Product images]. Retrieved March 18, 2025, from https://www.ridgid.com/ca/en/sectional-cable-tools

Skilled Trades BC. (2021). Book 2: Install fixtures and appliances, install sanitary and storm drainage systems. Plumber apprenticeship program level 2 book 2 (Harmonized). Crown Publications: King’s Printer for British Columbia.

Sioux Corporation. (n.d.). E-Series pressure washers [Product image]. Retrieved March 18, 2025, from https://sioux.com/e-series-pressure-washers

Trades Training BC. (2021). D-5: Maintain and repair sanitary and storm drainage systems. In: Plumber Apprenticeship Program: Level 2. Industry Training Authority, BC.

Media Attributions

All figures are used with permission from Skilled Trades BC (2021) unless otherwise noted.

- Figures 8-23 are from RIDGID/Emerson Electric Co. ‘s Sectional cable tools webpage and they are used with permission.

- Figure 24 Steam-powered drain cleaner [H4D2750 high pressure hot water washer] is from SIOUX Corporation and is used with permission.

A cross bore happens when one underground pipe accidentally goes through another pipe. For example, a new pipe might be drilled through a sewer pipe by mistake. This can be dangerous and cause clogs or leaks, so workers check carefully to make sure pipes don’t cross like this. (Section D-5.1)

A tool that helps workers find dangerous gases in the air that could catch fire or explode. It keeps people safe by warning them when gas levels are too high. (Section D-5.1)

A device that sends out signals through the air, like a radio station sending music or a walkie-talkie sending messages. It turns electrical signals into radio waves that can travel through the air to other devices, like radios or phones, that can receive and play the signals. (Section D-5.1)

A tool used to dig small holes in the ground. It has a long handle and a sharp, spiral bit at the end that you twist into the soil to make the hole. It's used for tasks like planting trees or installing posts. (Section D-5.1)

A special tool, named after the water closet, used to unclog toilets. It has a long, flexible rod with a spiral end that you insert into the toilet drain. When you turn the handle, the spiral helps break up or remove the blockage. (Section D-5.1)

An attachment fitted to the end of a drill rod or casing, designed to bore into the ground and remove soil or sediment during well installation. (Section D-5.1)